Description

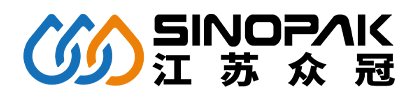

Washing Part:

The bottle enters the bottle washing machine through the transmission star wheel. The bottle clamp clamps the bottle mouth and turns it up 180 ° along the bottle washing guide rail to make the bottle mouth down. In the specific area of the bottle washing machine (determined by the water distribution plate – the bottle washing water is pumped into the water distribution plate by the bottle washing water pump, and then distributed to the bottle washing clamp by the water distribution plate through 16 pipelines), the nozzle of the bottle washing clamp sprays sterile water to wash the inner wall of the bottle. After washing and draining, the bottle is clamped by the bottle clamp and turned down along the guide rail for 180 ° to make the bottle mouth upward. The washed bottle is led out from the bottle washing machine through the transition steel pulley (pure water bottle washing) and transmitted to the next process – primary pulp filling.

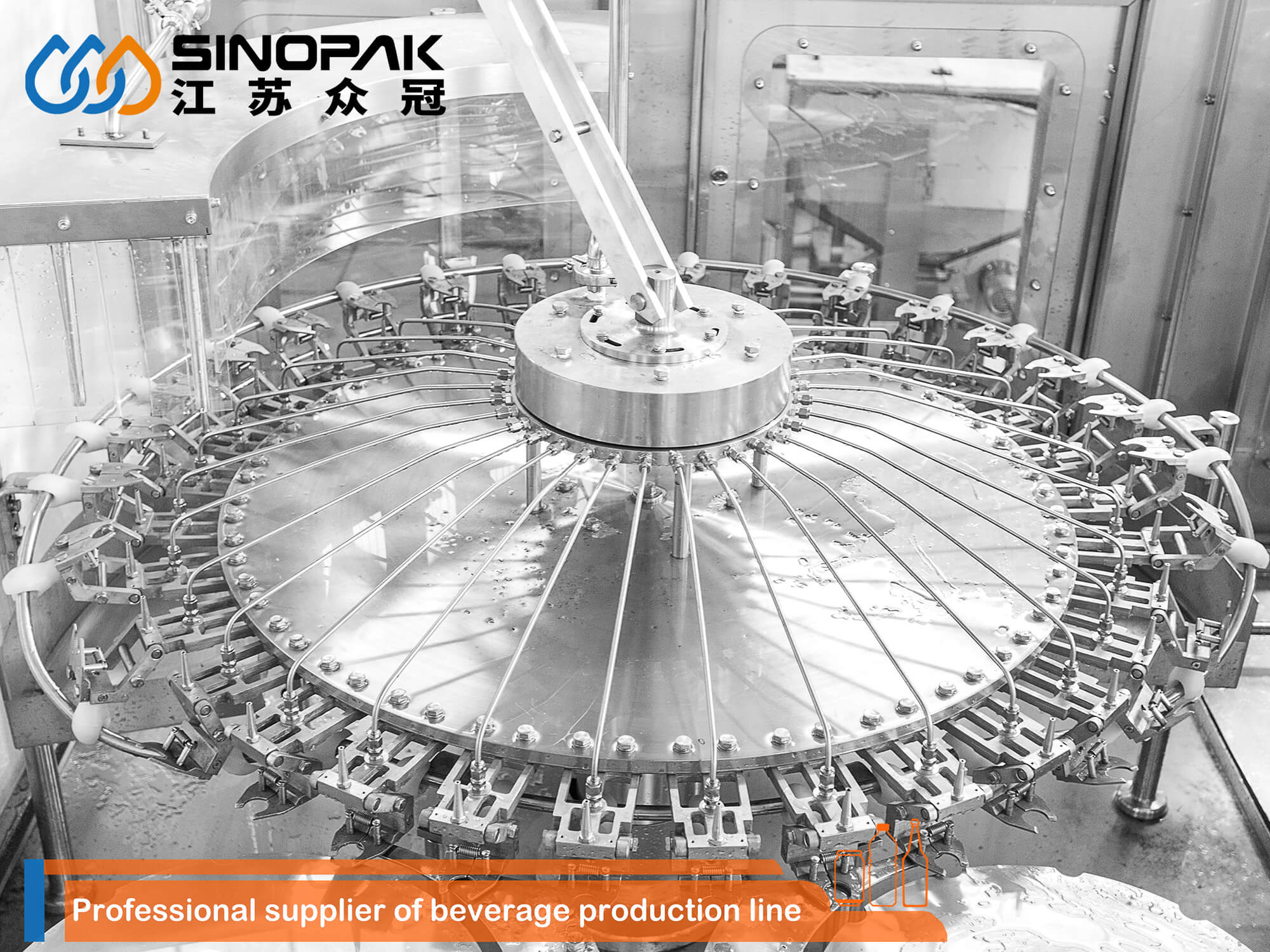

Pulp Filling Part:

During filling, the bottle adopts positioning bottle hanging device, which operates stably and reliably. The bottle mouth is under the action of the travel guide rail of the plug filling valve on the hanging plate, and then the valve opening mechanism is opened under the action of the cylinder to start injecting certain material pulps (non-contact filling). When the set liquid level of the stroke is reached, the valve closing mechanism of the filling valve is closed, and then the bottle is exported from the primary pulp filling through the transition steel puller and transmitted to the next process – Secondary fruit juice filling.

Juice Filling Part:

When filling, the bottle is lifted by cylinder, and the high-speed operation is stable and reliable. After the bottle mouth rises under the action of the cylinder, it is sealed with the filling valve, and then the valve opening mechanism is opened under the action of the cylinder to start filling. When the filling set liquid level is reached, the filling valve closing mechanism is closed, and then the bottle drops under the action of the pull-down cam and cylinder, and the filling is completed (to prevent the spraying phenomenon at the last disconnection from polluting the bottle mouth).

Capping Part:

After filling, the bottle enters the capping machine through the transmission star wheel. The rotation stop knife on the capping machine blocks the bottleneck and keeps the bottle upright and prevent rotation together with the outer bottleneck guard plate of the capping machine. The capping head rotates and rotates driven by the main shaft of the capping machine. Under the action of cam, the capping head can grasp, cover, screw and remove the cap, and complete the whole capping process.

The capping head adopts a magnetic constant torque device. When the capping head takes out the cover through the sub cover plate, the top cover sleeve butts the cover and centralizes the cover, so as to ensure the correct position of the cover in the capping die and ensure the capping quality. When the capping is completed, the capping head overcomes the magnetic slip and will not damage the bottle cap. At the same time, when the capping head rises, the top cover rod will push the cap out of the capping die.

The capping disc transmits power to the capping head through the pin wheel to ensure that its movement is synchronized with the capping machine. The bottle cap enters the capping disc through the cap channel, and then the bottle cap transmission star wheel transmits the bottle cap separately to the capping head according to the station.

Machine Parameters

| Project Name:Fruit Juice With Pulp Hot Filling Machine | ||||||

| Model | RXGGF | RXGGF | RXGGF | RXGGF | RXGGF | RXGGF |

| 14-12-12-5 | 16-12-16-5 | 24-16-24-8 | 32–24-32-8 | 40-32-40-10 | 50-32-50-12 | |

| Washing Nos | 14 | 16 | 24 | 32 | 40 | 50 |

| Pulp filling Nos | 12 | 12 | 16 | 24 | 32 | 32 |

| Filling Nos | 12 | 16 | 24 | 32 | 40 | 50 |

| Capping Nos | 5 | 5 | 8 | 8 | 10 | 12 |

| Capacity(BPH) | 3500 | 5000 | 10000 | 12000 | 15000 | 18000 |

| Suitable bottle | Glass bottle and PET bottle | |||||

| Bottle Volume | 150ml to 2.5Ltr (Customized) | |||||

| Bottle diameter(mm) | Dia50-Dia115 | |||||

| Bottle height | 160-320mm | |||||

| Pulp size(mm) | 2-5mm diameter(Customized) | |||||

| Compress air pressure(Mpa) | 0.3-0.4 | |||||

| Washing medium | Aspetic water | |||||

| Rinsing pressure(Mpa) | >0.06 <0.2 | |||||

| Filling temperature | 85~90℃ | |||||

| (℃) | ||||||

| Filling theory | Micro negative pressure filling/ Plug valve pushing pulp filling | |||||

| Application | Fruit juice with pulp hot filling machine | |||||

| Total powder | 3KW | 4KW | 4KW | 4KW | 5.5KW | 5.5KW |

| Measurement | 3000*1770*2700 | 3700*2260*2700 | 4400*2050*2650 | 5000*2250*2700 | 6200*3300*2700 | 7360×3460×2650 |

| (mm) | ||||||

| Weight | 3200kg | 6000kg | 10000kg | 12000kg | 15000kg | 18000kg |

Configuration List

| No | Name | Brand |

| 1 | Main motor | ABB |

| 2 | Cap unscrambler motor | FEITUO(China) |

| 3 | Conveyor motor | FEITUO(China) |

| 4 | Rinsing pump | CNP (China) |

| 5 | Solenoid valve | FESTO |

| 6 | Cylinder | FESTO |

| 7 | Air-T contactor | FESTO |

| 8 | Pressure adjust valve | FESTO |

| 9 | Inverter | MITSUBISHI |

| 10 | Power switch | MIWE(TAIWAN) |

| 11 | Contactor | SIEMENS |

| 12 | Relay | MITSUBISHI |

| 13 | Transformer | MIWE(TAIWAN) |

| 14 | Approx switch | TURCK |

| 17 | PLC | MITSUBISHI |

| 18 | Touch screen | Pro-face |

| 19 | Air components | FESTO |

| 20 | AC Contactor | Schneider |

| 21 | Micro relay | MITSUBISHI |