Description

Main Features:

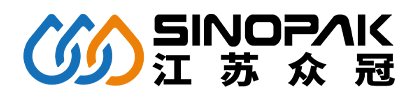

- The filling valve adopts high-precision mechanical valve, which has fast filling speed and high liquid level precision.

- The filling cylinder adopts a sealing cylinder designed by 304 material to realize micro-negative pressure gravity filling.

- Filling valve flow rate is more than 125ml / s.

- The main drive adopts a combination of a toothed belt and a gearbox open transmission, which has high efficiency and low noise.

- The main drive adopts variable frequency stepless speed regulation, and the whole machine adopts PLC industrial computer control; the sealing machine and the filling machine are connected by a coupling to ensure the synchronization of the two machines.

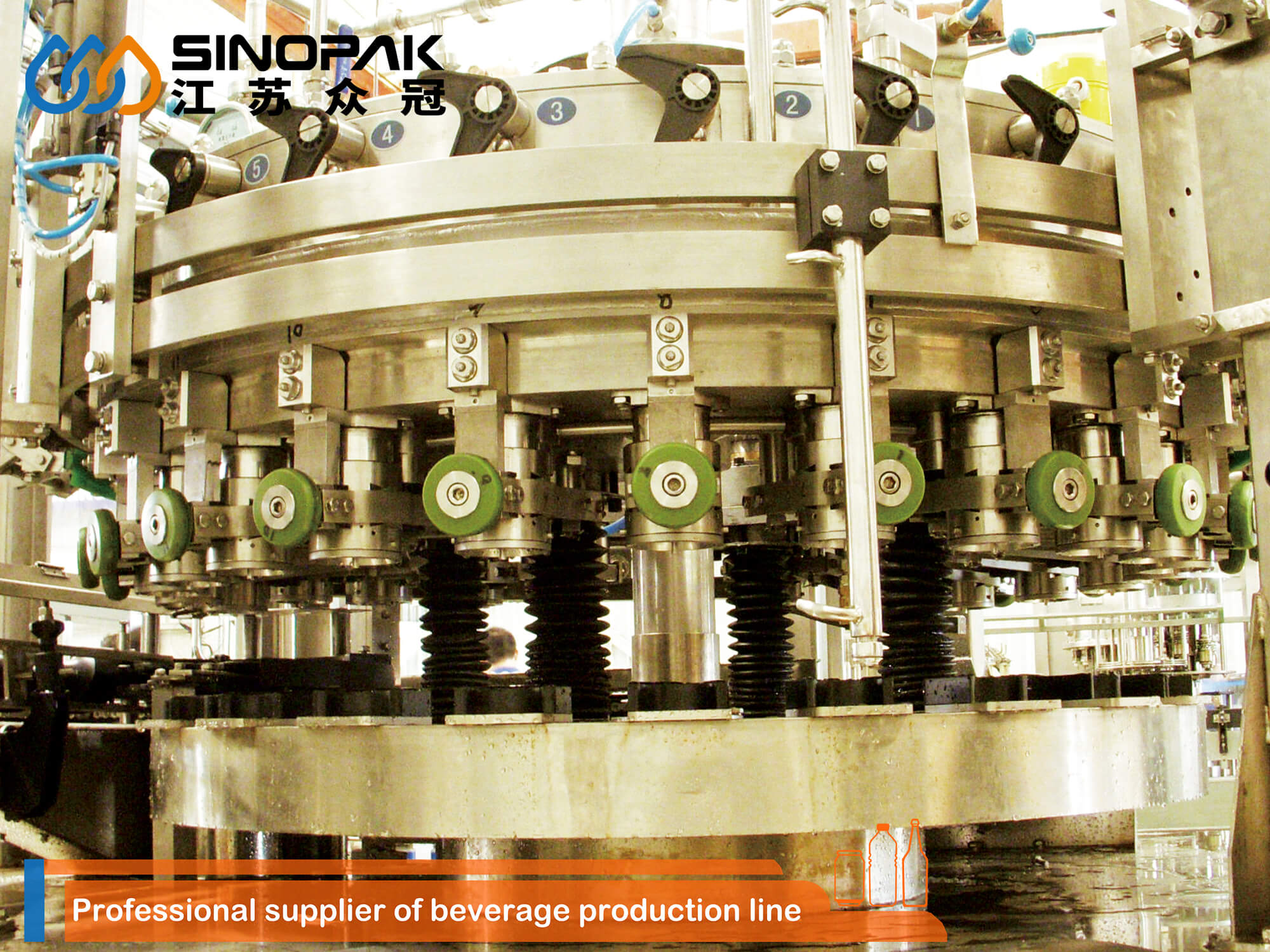

- The sealing technology is from Ferrum Company of Swiss .

- The sealing roller is quenched with high hardness alloy (HRC>62), and the sealing curve is precision machined by optical curve grinding to ensure the quality of sealing. The guide bottle system can be changed according to the bottle type.

- The sealing machine introduces Taiwan sealing rollers and indenters to ensure the quality of the sealing. This machine has a can bottom cover, no cans and no cover control system to ensure the normal operation of the machine and reduce the cover loss rate.

Working process:

- This machine has the remarkable characteristics of fast filling speed, consistent liquid level in the tank to the top of the tank after filling, stable operation of the whole machine, good sealing quality, beautiful appearance, convenient use and maintenance, etc.

- Using the normal pressure filling principle, when the empty can enters the lifting tray through the dial, the filling valve and the empty can are aligned, the empty can is raised and sealed, and the valve port of the filling valve is automatically opened. Stop filling when the valve return port is blocked. The filled can is sent to the head of the sealing machine through the hook chain, and the lid is sent to the can mouth through the cap feeder and the pressure head. When the tank holding mechanism is raised, the pressure head presses the tank mouth, and the sealing wheel is pre-sealed and then sealed.

Configuration:

- The main electrical components of this machine adopt high-quality configuration such as Siemens PLC, Omron proximity switch, etc., and are designed into a reasonable configuration form by the company’s senior electrical engineers. The entire production speed can be set by itself on the touch screen according to the requirements, all common faults are automatically alarmed, and the corresponding fault causes are given. According to the severity of the fault, the PLC automatically judges whether the host can continue to run or stop.

- Functional characteristics, the whole machine has various protections for the main motor and other electrical appliances, such as overload, overvoltage and so on. At the same time, the corresponding various faults will be automatically displayed on the touch screen, which is convenient for users to find the cause of the fault. The main electrical components of this machine adopt international famous brands, and brands can also be formulated according to customer requirements.

- The whole machine is framed by stainless steel plate, which has good waterproof and anti-rust functions.

Electric Part & Safe Device & Automation:

- When accident system automatic stop & alarm

- Emergency switch when accident

- PLC control full-automatic working, inverter in-build, speed adjustable

- Touch-screen Control Panel, easy operate

- Famous Omron brand sensor & other electric parts adopted, ensure system heavy duty running

Capping Part :

- Cap distributing chute is equipped with reverse cap stop and reverse cap pick-out mechanism.

- Cap distributing chute is equipped with a photocell switch to stop the capper when there is no cap inside the chute.

- The capper is equipped with inlet bottle detection switch.

- Centrifugal way of cap arranging is adopted to reduce damage of caps.

Machine Base & Machine Construction::

- 304 stainless steel frame

- Excellent start wheel design, easy change over parts

- Machine Base with anti-rust process, ensure the forever antirust

- All seal where liquid may Leakage & base neck come with rubber, water proof

- Manual lubrication system

Machine Parameters

| Model | TFS-C 6-1 | TFS-C 12-1 | TFS-C 12-4 | TFS-C 20-4 | TFS-C 30-6 | TFS-C 60-8 |

| Capacity | 600-800 CPH (cans per hour) | 1500-1800 CPH (cans per hour) | 4500-5000 CPH (cans per hour) | 12000-13000 CPH (cans per hour) | 18000-19000 CPH (cans per hour) | 35000-36000 CPH (cans per hour) |

| Suitable bottle | PET CAN, ALUMINUM CAN, IRON CAN AND SO ON | |||||

| Filling precision | ≤±2mm | |||||

| Filling pressure (Mpa) | ≤0.4Mpa | |||||

| Machine power | 2.2 | 2.2 | 2.2 | 3.5 | 3.5 | 5 |

| Weight (kg) | 1200 | 1500 | 1800 | 2500 | 3200 | 3500 |