We are devoted to supplying complete solution for the carbonated beverage filling plant ,including Water treatment system /Carbonated Beverage Processing , Mixing , Carbonation System / Washing filling capping machine / liquid nitrogen dosing system / Auto Bottle Checker / Bottle Spraying Warmer /Bottle Blow Dryer / Laser Inkjet Printer / Automatic labeling machine / Automatic packing machine / Automatic Conveyor System / Automatic Palletizer system…..etc.

Hot filling: 115℃/125℃(5-15S)→85℃-92℃

Mid-temp filling: 115℃/125℃(5-15S)→65℃-72℃

CIP cleaning, self sterilizing,

Precise and reliable sterilizing temperature control.

The CIP cleaning system uses high temperature and high concentration cleaning liquid to exert a strong effect on the equipment and devices to clean the contact surface with the beverage.

The Fruit Juice Hot Filling Machine equipped with the Wash-filling-capping 3-in-1 unit is designed for the production of glass or PET bottled drinking juice.

It’s mainly used in sterilizing PET bottle mouth and inside of caps,by hot drink high temperature already fill in bottle to sterilize.

The machine can reduce the temperature hot filling drinks from 80-90℃ to 30℃-40℃,or increase temperature of cold filling carbonated drink from 8-10℃ to 36℃-40℃.Capacity 5000-36000 bottle/hour,spray time :15-20 minutes.

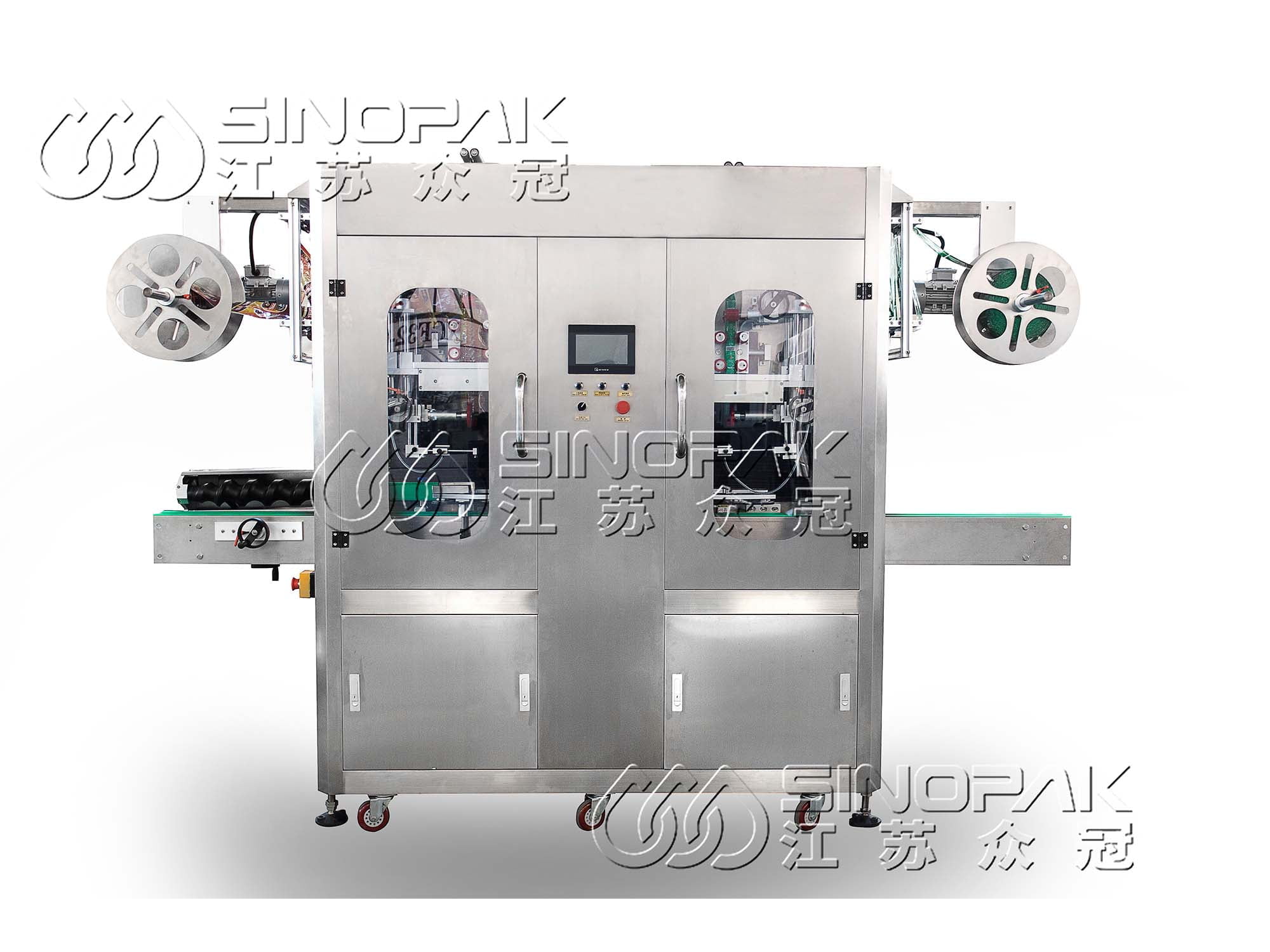

The mainly used for container labeling cylindrical shape of detergents, beverages, mineral water, food etc.

Gantry Palletizer Machine could independent finish products feeding,grouping arrange,empty pallet feeding, whole layer palletizing and full pallet feeding out works in continuously and automatically.

We understand the importance of efficient and reliable machinery in the beverage industry, which is why we use the latest technology and equipment to manufacture our products.