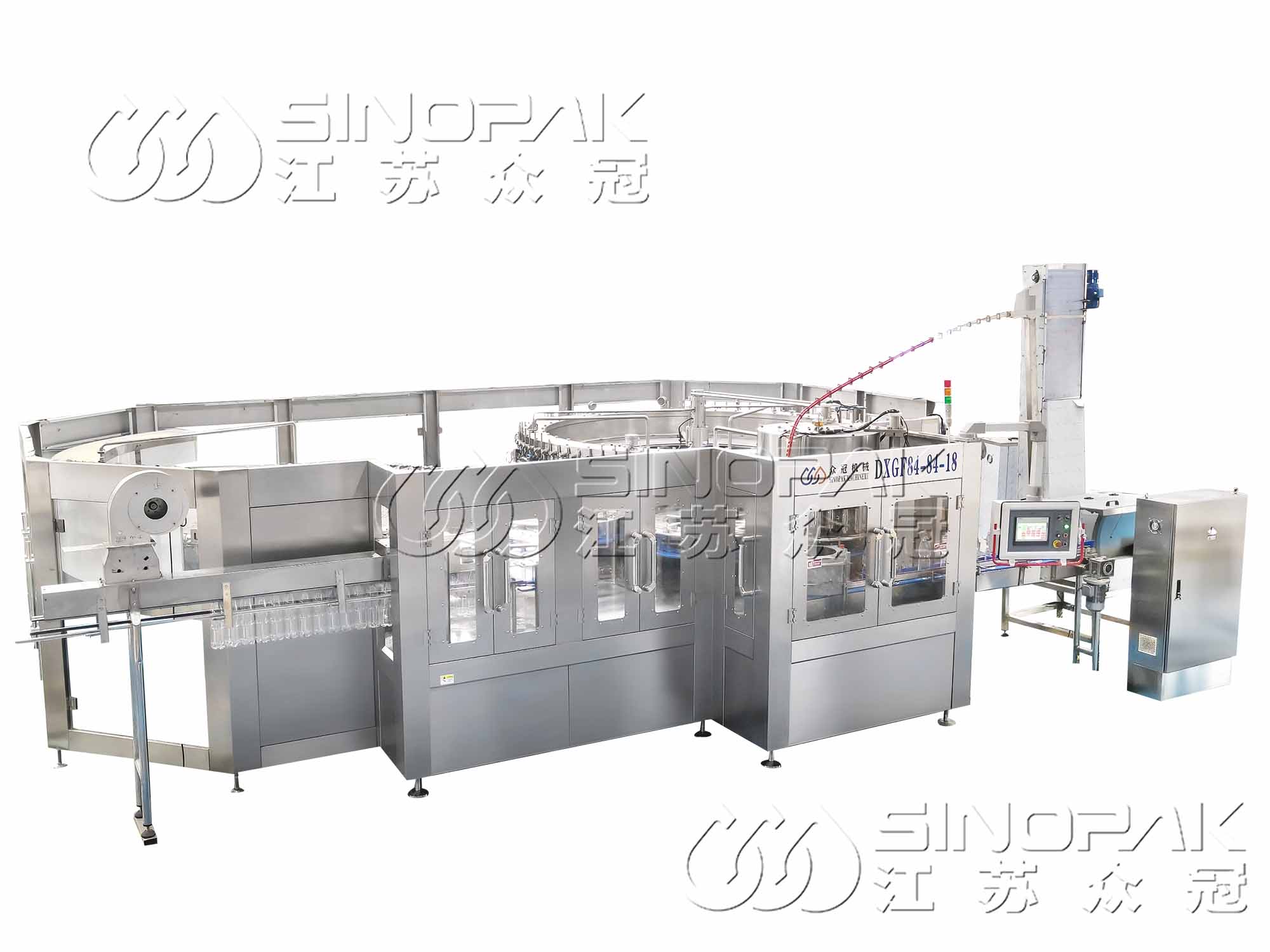

We are devoted to supplying complete solution for the carbonated beverage filling plant ,including Water treatment system /Carbonated Beverage Processing , Mixing , Carbonation System / Washing filling capping machine / liquid nitrogen dosing system / Auto Bottle Checker / Bottle Spraying Warmer /Bottle Blow Dryer / Laser Inkjet Printer / Automatic labeling machine / Automatic packing machine / Automatic Conveyor System / Automatic Palletizer system…..etc.

Carbonated beverage mixing system with reasonable & high efficiency structure , high mix precision , CO2 mixing fully, two stage of cooling, two carbonation merits. Mainly is suitable for kinds of carbonated drink’s mix processing and carbonation, also may use in the paste drink, the fermentation drink and so on other soft drinks’ mix processing.

Cooling capacity : 51000 ~ 194000 Kcal/hr Function :Water cooled screw chiller

Automatic or Semi Automatic PET Blow Moulding Machine With Capacity 100-12000BPH.

Cooling ct is mainly used for carbonated soft drink, such as cola, soda water and so on. The final filling temperature will be around 0-5℃. The machine design is shorten the time for the drink material contact with outside, increase the sanitation condition throughout economy benefit.apacity : 51000 ~ 194000 Kcal/hr Function :Water cooled screw chiller

Because carbonated beverages are filled at low temperature (commonly 4-10℃), and the room temperature in summer is much higher than this, in such an environment, the moisture in the air is very easy to condense and dew on the outer surface of the bottle, which is used for subsequent packaging and operation. Inconvenience such as labeling.

The mainly used for container labeling cylindrical shape of detergents, beverages, mineral water, food etc.

Automatic Film shrinking packing machine have L automatic type , Liner automatic type and a semi-auto type.

Gantry Palletizer Machine could independent finish products feeding,grouping arrange,empty pallet feeding, whole layer palletizing and full pallet feeding out works in continuously and automatically.

Bottled Carbonated Beverage (e.g., Soft Drinks, Soda Water, Beer) Filling is a Process with Extremely High Technical Requirements.

The core challenge lies in maintaining the stability of carbon dioxide (CO₂) in the beverage, preventing its loss and deterioration.

Below are the common problems encountered during the filling process, their causes, and the corresponding solutions.

Problem Manifestation:

When the bottle is opened, there is no “hiss” sound, bubbles are insufficient, and the taste is flat (commonly referred to as “flat” or “losing carbonation”).

Causes:

Check the CO₂ mixer process first:

Low mixing pressure: The pressure in the mixing tank or carbonator is insufficient to dissolve enough CO₂.

High water temperature: Cooling efficiency of the chiller is inadequate. The solubility of CO₂ in water is inversely proportional to temperature—the higher the temperature, the less CO₂ can dissolve.

Low CO₂ purity or insufficient supply: The CO₂ gas contains air or other non-condensable gases, which not only occupy pressure but also hinder CO₂ dissolution.

Insufficient mixing time: Contact time between water and CO₂ is too short to reach saturation.

Equipment malfunction: Carbonator nozzle blockage, faulty pressure gauge, reduced pump efficiency, etc.

Filling temperature too high: CO₂ solubility decreases as beverage temperature increases, causing CO₂ to escape more easily.

Insufficient counter-pressure: Before filling, the filler injects high-pressure CO₂ into the empty bottle (called counter-pressure) to balance with the pressure in the product tank. If the counter-pressure is too low, when the beverage enters the bottle, the sudden pressure drop causes CO₂ to escape rapidly.

System leakage: Even tiny leaks in the product tank, pipelines, or valves of the filling machine can lead to pressure loss and CO₂ release.

Filler valve seal failure: Aging or worn seals in the filler valve cause gas leakage during filling.

Bottle neck or cap defects: Improper neck dimensions or flaws in the bottles, and defective cap liners or loose sealing, can cause slow CO₂ leakage after filling.

Solutions:

Strictly control filling temperature: Cool beverages to below 4 °C (typically 1–4 °C) before filling to maximize CO₂ solubility.

Precisely control counter-pressure: Ensure the filler counter-pressure setting is slightly higher (approx. 0.1–0.2 bar) than the beverage’s saturation pressure (which depends on temperature and carbonation level) to maintain stable balance.

Regular equipment inspection and maintenance: Implement a strict inspection schedule to check pipelines, valves, and seals, and replace worn components promptly to eliminate leaks.

Use high-quality bottles and caps: Strengthen incoming quality inspection of packaging materials, ensuring bottle neck dimensions and roundness meet standards, and that caps and liners have excellent sealing performance.

Regular carbonation level testing: Use pressure gauges, carbonation testers, or CO₂ analyzers for online or offline sampling to monitor carbonation levels and make timely adjustments.

Problem Manifestation:

The liquid level in finished bottles is inconsistent—some are overfilled, while others are underfilled.

Causes:

Uneven or blocked filling valve flow rate: The discharge speed of each filling valve is inconsistent, or valve orifices are partially blocked by impurities.

Poor exhaust (for isobaric fillers): During filling, the gas inside the bottle must be smoothly discharged. If the exhaust valve is clogged or improperly adjusted, gas cannot escape properly, preventing the liquid from reaching the preset level.

Mechanical malfunction: Wear or misalignment of the filling valve’s opening/closing mechanism causes inconsistent filling times.

Bottle height inconsistency: Though less common, if the supporting surface at the bottom of bottles varies too much, it can affect the accuracy of liquid level sensors.

Solutions:

Regularly clean and calibrate filling valves to ensure smooth flow and consistent discharge speed.

Inspect and clean the exhaust system to keep exhaust channels unobstructed.

Perform unified mechanical adjustments by qualified technicians to standardize filling valve calibration.

Use bottles that meet quality standards.

Problem Manifestation:

During filling, excessive foam is generated, leading to underfilling, splashing, inaccurate liquid levels, and significant CO₂ loss.

Causes:

Beverage temperature too high: Same reason as for CO₂ loss—higher temperature reduces CO₂ solubility and increases foaming.

Insufficient counter-pressure: A large pressure difference between the bottle and the product tank causes the beverage to foam instantly when entering the bottle, similar to “opening champagne.”

Excessive inlet and filling speed: Excessively fast liquid flow rate creates strong impact against the bottle bottom, generating foam.

Solutions:

Reduce filling temperature.

Properly increase counter-pressure.

Adjust inlet and filling speed: Adopt multi-stage filling—start slowly, accelerate after the liquid covers the bottle bottom, then slow down again near the full level.

To ensure the quality of bottled carbonated soft drink filling, a systematic approach must be adopted:

Precise Process Parameter Control: Temperature, pressure, and time are the three core process parameters that must be continuously monitored and maintained within optimal ranges.

Preventive Equipment Maintenance: Establish strict routines for daily inspections, regular servicing, and major overhauls to prevent failures before they occur.

Packaging Material Quality Control: High-quality bottles and caps are the foundation of successful filling.

End-to-End Quality Control: Implement comprehensive quality monitoring and traceability throughout the entire process—from raw materials and packaging materials, to the filling process, and finally to the finished product.

Personnel Training: Operators and maintenance staff must undergo thorough training to fully understand the principles, operate equipment skillfully, and detect abnormalities in time.

By systematically addressing the above issues, the efficiency and product quality of carbonated beverage filling can be significantly improved, losses can be reduced, and consumers are guaranteed the best taste and quality when the product reaches them.

We would love to hear about your project and discuss how wecan help. To schedule a meeting with our team, simply fill outthe form in this section.

We understand the importance of efficient and reliable machinery in the beverage industry, which is why we use the latest technology and equipment to manufacture our products.