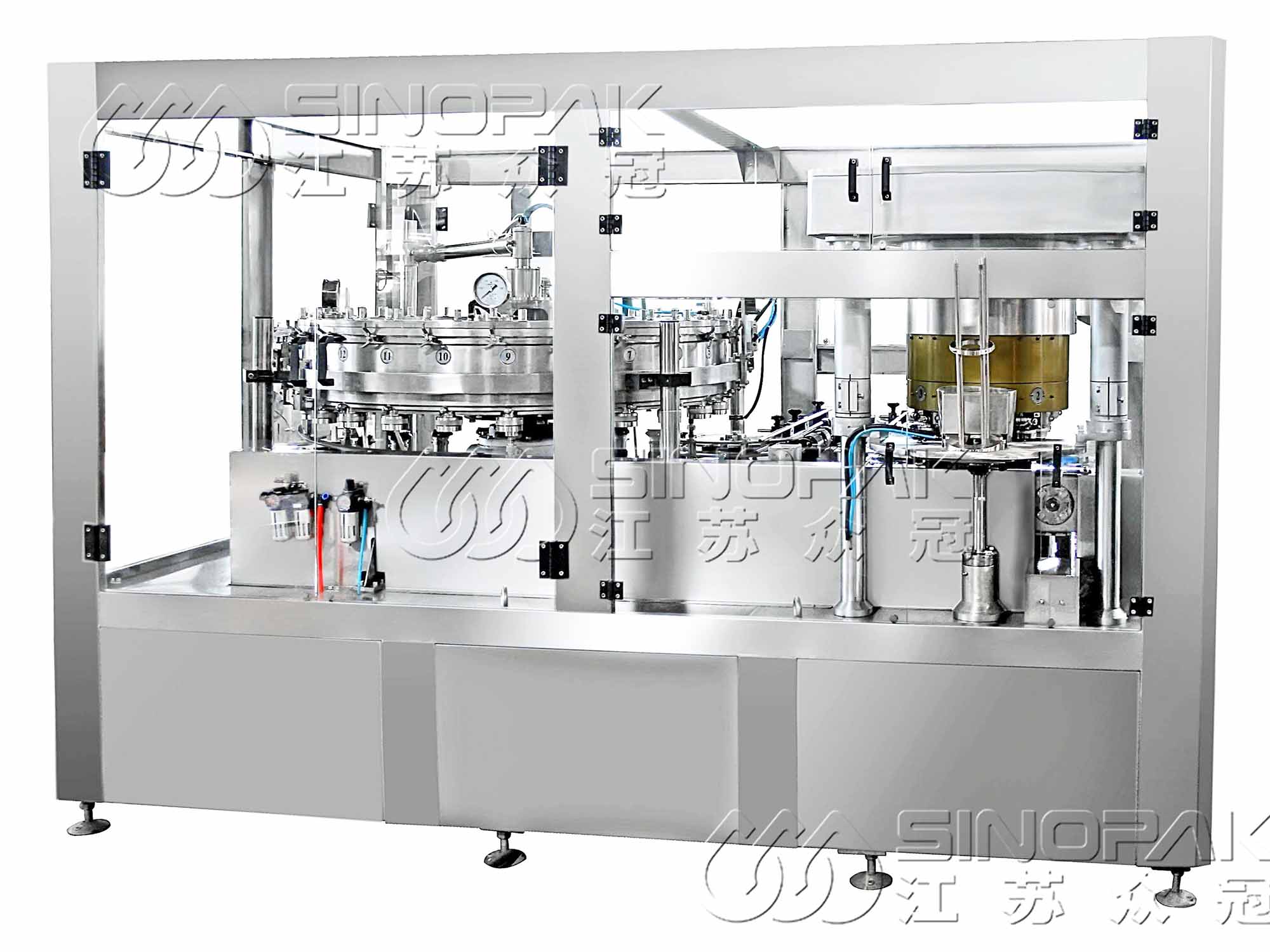

Can filling and capping machine, suitable for cans containing or not containing gas, beverages, and beer. It is another masterpiece carefully developed for products with different can and bottle types, taking a solid step for our company to expand into the international market. Exported to Western countries such as Europe and America, meeting local craft beer filling requirements!

Used for pure water, mineral water and other bottled water, water for food and beverage production.

Carbonated beverage mixing system with reasonable & high efficiency structure , high mix precision , CO2 mixing fully, two stage of cooling, two carbonation merits. Mainly is suitable for kinds of carbonated drink’s mix processing and carbonation, also may use in the paste drink, the fermentation drink and so on other soft drinks’ mix processing.

The working principle of tank unloading adopts main section propulsion, dual guide positioning, and flow control to ensure that the tank will not be squeezed, deformed, or tipped when it moves with linear freedom.

Our easy to use twist rinser is designed to rinse particles out of your empty cans prior to filling them.

We recommend using a twist rinse with your canning line because even the smallest contaminant can contain spoilage microorganisms that can create off-flavors in your final canned product.

It is widely used in the filling and sealing of cans such as beverages, mineral water and juice and other non-carbonated drinks.It has the characteristics of fast filling and sealing speed, consistent liquid level in the tank to the tank opening after filling, stable operation of the whole machine, good sealing quality, beautiful appearance, convenient use and maintenance, touch screen operation, frequency conversion speed regulation, etc. It is an ideal filling and sealing equipment for various juice beverages and water.

Because carbonated beverages are filled at low temperature (commonly 4-10℃), and the room temperature in summer is much higher than this, in such an environment, the moisture in the air is very easy to condense and dew on the outer surface of the bottle, which is used for subsequent packaging and operation. Inconvenience such as labeling.

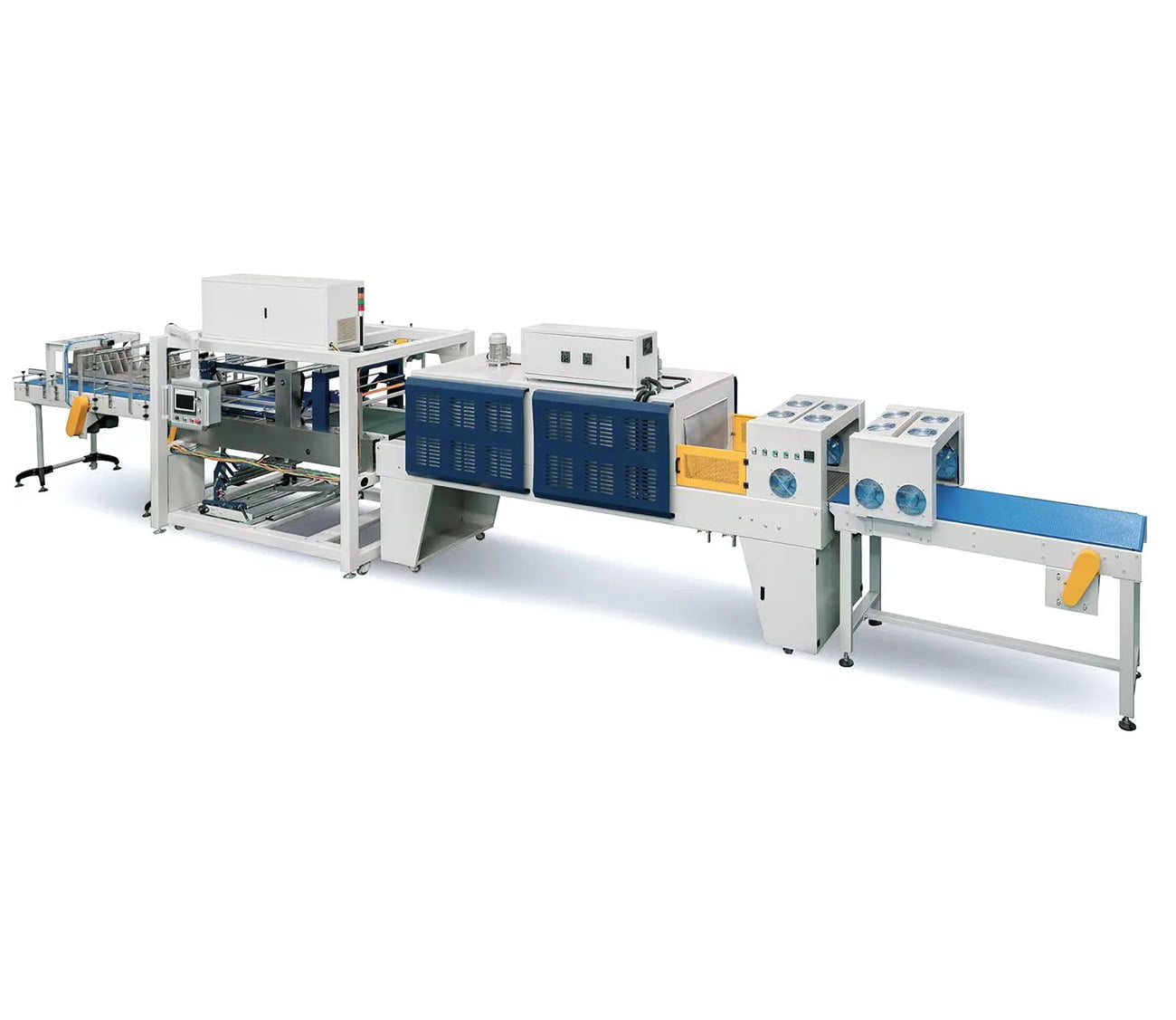

Automatic Film shrinking packing machine have L automatic type , Liner automatic type and a semi-auto type.

Gantry Palletizer Machine could independent finish products feeding,grouping arrange,empty pallet feeding, whole layer palletizing and full pallet feeding out works in continuously and automatically.

We understand the importance of efficient and reliable machinery in the beverage industry, which is why we use the latest technology and equipment to manufacture our products.