Description

Main Features:

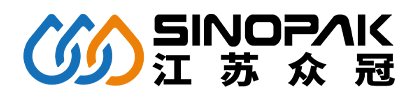

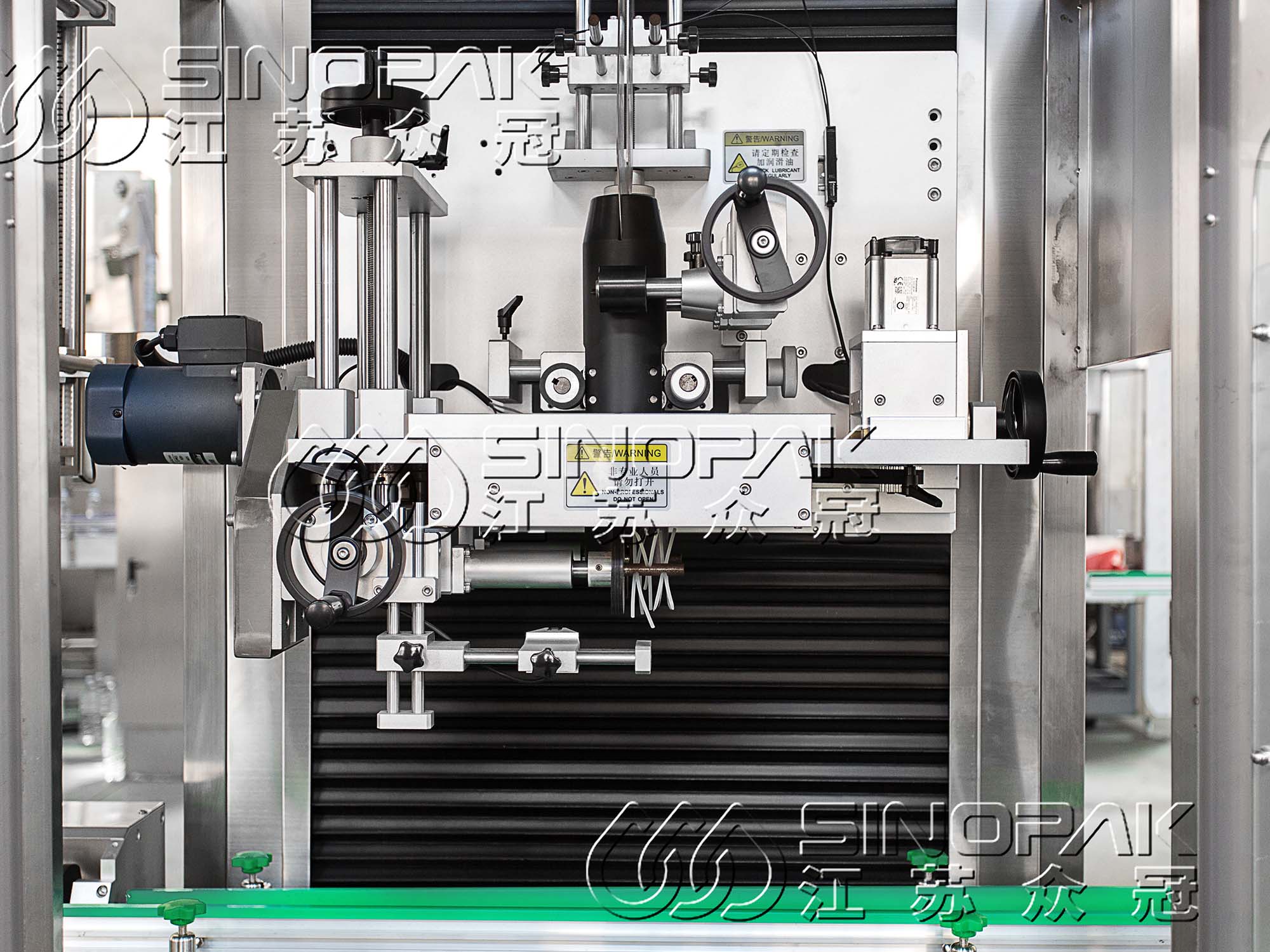

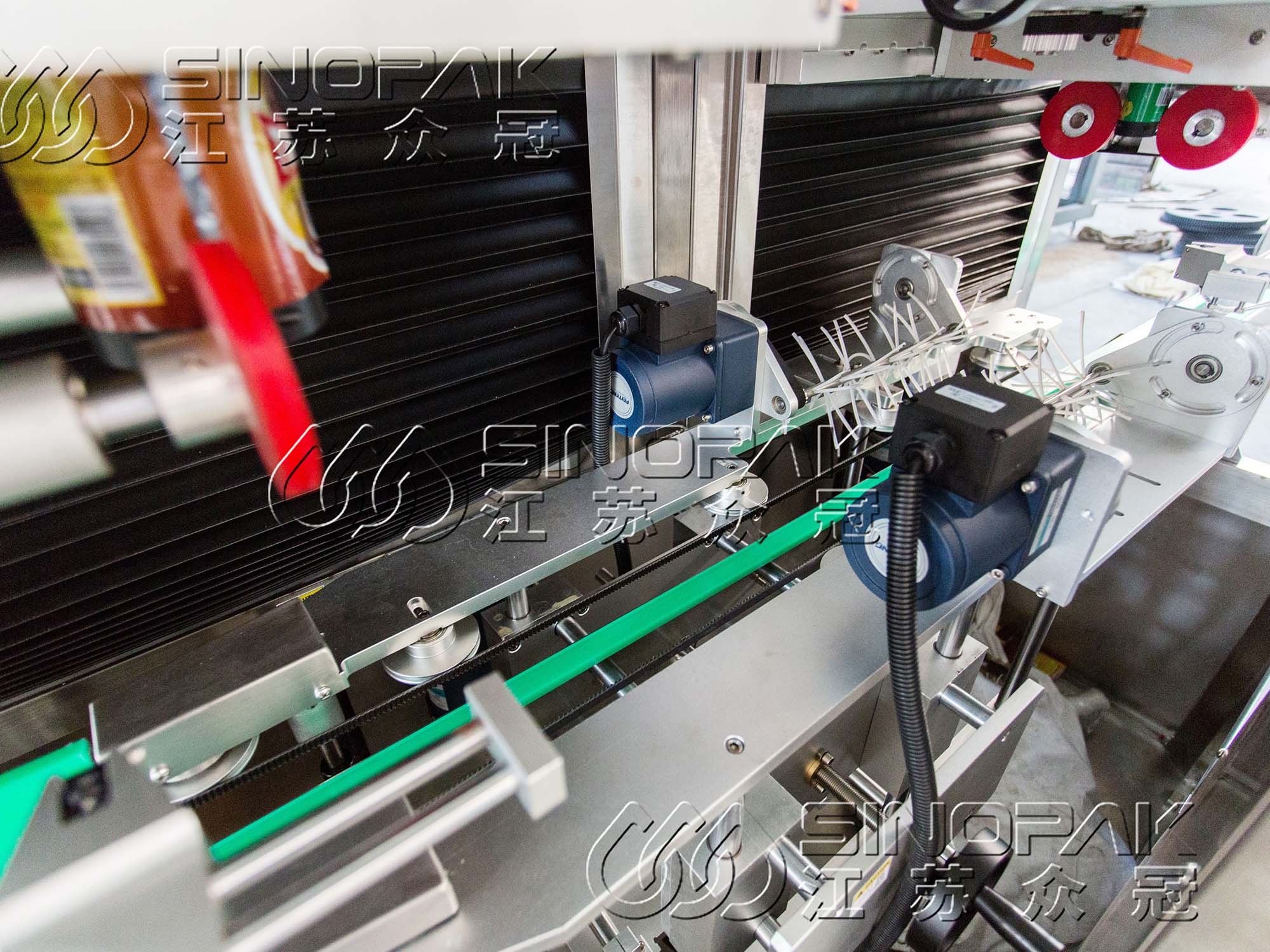

- The whole machine adopts stainless steel and high-quality aluminum, well-structured, compact and easy to adjust.

- Without anchor bolts can be easily mobile, flexible space with the production.

- Shrink film label rack, with adjustable brake, and paper tube according to label 5 “~ 10” to facilitate adjustment.

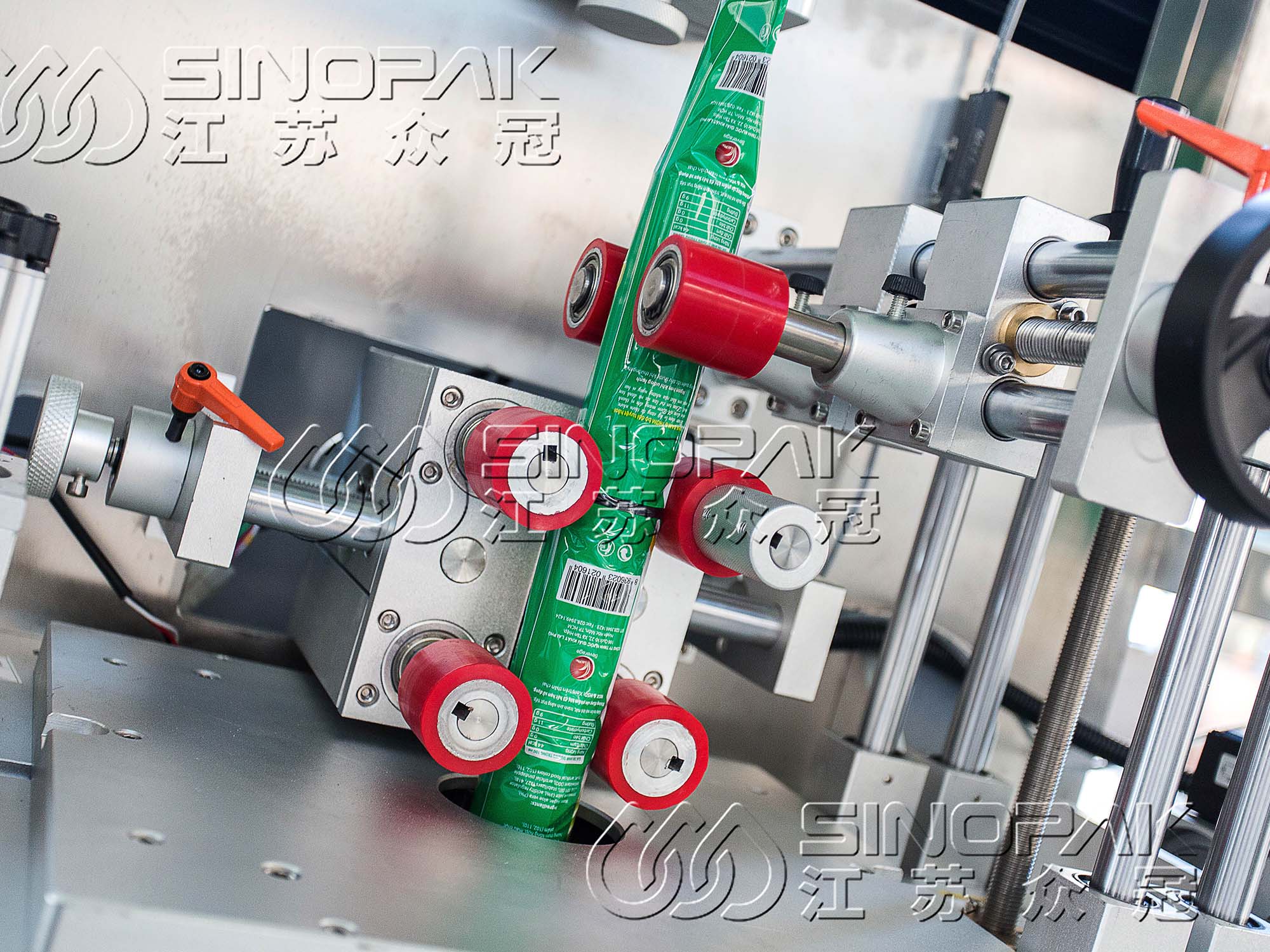

- Unique set of standard methods, the use of compression-type sets of tender, in a convenient and reasonable.

- Automatic feed motors, at the same time leveling materials shrink film tension adjustment.

- Volume label detection system ensure that the minimum error.

- Unique design of the knife is special in the framework, can change blocks ATC freely, ATC quickly and easily.

- Center column clamping system, change quickly and without any tools.

- Label positioning device, according to the demand for container shape, position adjustment can be synchronized movements.

- Hours bottle-screw, positioning belt, chain adjustment using synchronous manner, and speed adjustment is simple, quick.

- Adopt Japanese servo motor and high-sensitivity photoelectric, standard length is precision

- Stainless steel electrical control box, control the use of Japan’s Mitsubishi PLC.

- Adopt advanced automatic control technology of the man-machine interface, the key electrical components are adopted internationally renowned products

Parameters:

| Main technical parameters of the equipment | |||||

| Model | SL-100 | SL-200 | SL-300 | SL-400 | SL-500 |

| Voltage | AC220V, 50/60HZ, 1.5-2KW (Host machine) AC380V,50/60HZ, 18KW (Shrinking machine) | AC220V, 50/60HZ, 1.5 KW (Host machine) AC380V,50/60HZ, 18KW (Shrinking machine) | AC220V, 50/60HZ, 2.5 KW (Host machine) AC380V,50/60HZ, 24KW (Shrinking machine) | AC220V, 50/60HZ, 3 KW (Host machine) AC380V,50/60HZ, 36KW (Shrinking machine) | AC220V, 50/60HZ, 3 KW (Host machine) AC380V,50/60HZ, 36KW (Shrinking machine) |

| Production speed | 6000 BPH | 9000-12000 BPH | 15000-18000 BPH | 22000-24000 BPH | 28000-30000 BPH |

| Diameter of bottle body | ∮28mm-∮125mm | ∮28mm-∮125mm | ∮28mm-∮125mm | ∮28mm-∮125mm | ∮28mm-∮125mm |

| Length of label | 30mm-250mm | 30mm-250mm | 30mm-250mm | 30mm-250mm | 30mm-250mm |

| Thickness of label | 0.035mm-0.13mm | 0.03mm-0.13mm | 0.03mm-0.13mm | 0.03mm-0.13mm | 0.03mm-0.13mm |

| Material of label | PVC、 PET、 OPS | PVC、 PET、 OPS | PVC、 PET、 OPS | PVC、 PET、 OPS | PVC、 PET、 OPS |

| Size (label sleeving host machine) | L2000mm*W850mm* H2000mm | L780mm*W1200mm* H2000mm | L2100mm*W1100mm*H2000mm | L2100mm*W850mm* H2000mm | L2500mm*W1200mm*H2000mm |

| Size (Bulk of steam shrinking label) | L1800mm*W500mm* H1500mm | L1800mm*W500mm* H1500mm | L1800mm*W500mm* H1500mm | L1800mm*W500mm* H1500mm | L1800mm*W500mm* H1500mm |

| Steam shrinking tunnel (quantity of steam) | 20Kg/H | 30Kg/H | 30Kg/H | 50Kg/H | 50Kg/H |

Configuration List:

| List of Standard electricl appliance Configuration | |||||

| Module name | Electric appliance name | Type | Quantity | Merchant | Place of production |

| Machine frame fluctuation unit | Low power a-c dynamo | 5IK90GU-CF-5GU30KB | 1 | TWT | Taiwan |

| Clean-down unit | Low power a-c dynamo | 5IK120A-CFT | 1 | TWT | Taiwan |

| Feeding unit | Low power a-c dynamo | RV50-15K-180 | 1 | TWT | Taiwan |

| Frequency converter | VFO-0.25KW | 1 | Panasonic | Japan | |

| Photoelectricity inductor | CX-421 | 1 | Panasonic | Japan | |

| Bottle Carrying unit | Low power a-c dynamo | 5IK90GN-YFT-5GN20K | 1 | TWT | Taiwan |

| Frequency converter | VFO-0.25KW | 1 | Panasonic | Japan | |

| Bottle Separation unit | Low power a-c dynamo | 5IK90GN-YF-5GN10K | 1 | TWT | Taiwan |

| Frequency converter | VFO-0.25KW | 1 | Panasonic | Japan | |

| Hairbrush unit | Low power a-c dynamo | 4IK25GN-CFT-4GN3K | 2 | TWT | Taiwan |

| Cutter head unit | Cutter head servo motor | MHMD042P1U(400w) | 1 | Panasonic | Japan |

| Cutter head servo driver | MBDDT2210003(400w) | 1 | Panasonic | Japan | |

| Minitype photoelectricity inductor | PM-L44 | 2 | Panasonic | Japan | |

| Driving unit | Driving servo motor | MHMD042P1U(400w) | 1 | Panasonic | Japan |

| Driving servo driver | MBDDT2210003(400w) | 1 | Panasonic | Japan | |

| Electric eye unit | High speed fibre-optical inductor | FX-301 | 1 | Panasonic | Japan |

| Bottle monitor unit | Photoelectricity inductor | CX-442 | 1 | Panasonic | Japan |

| Conveyor unit | Frequency converter | VFO-0.75KW | 1 | Panasonic | Japan |