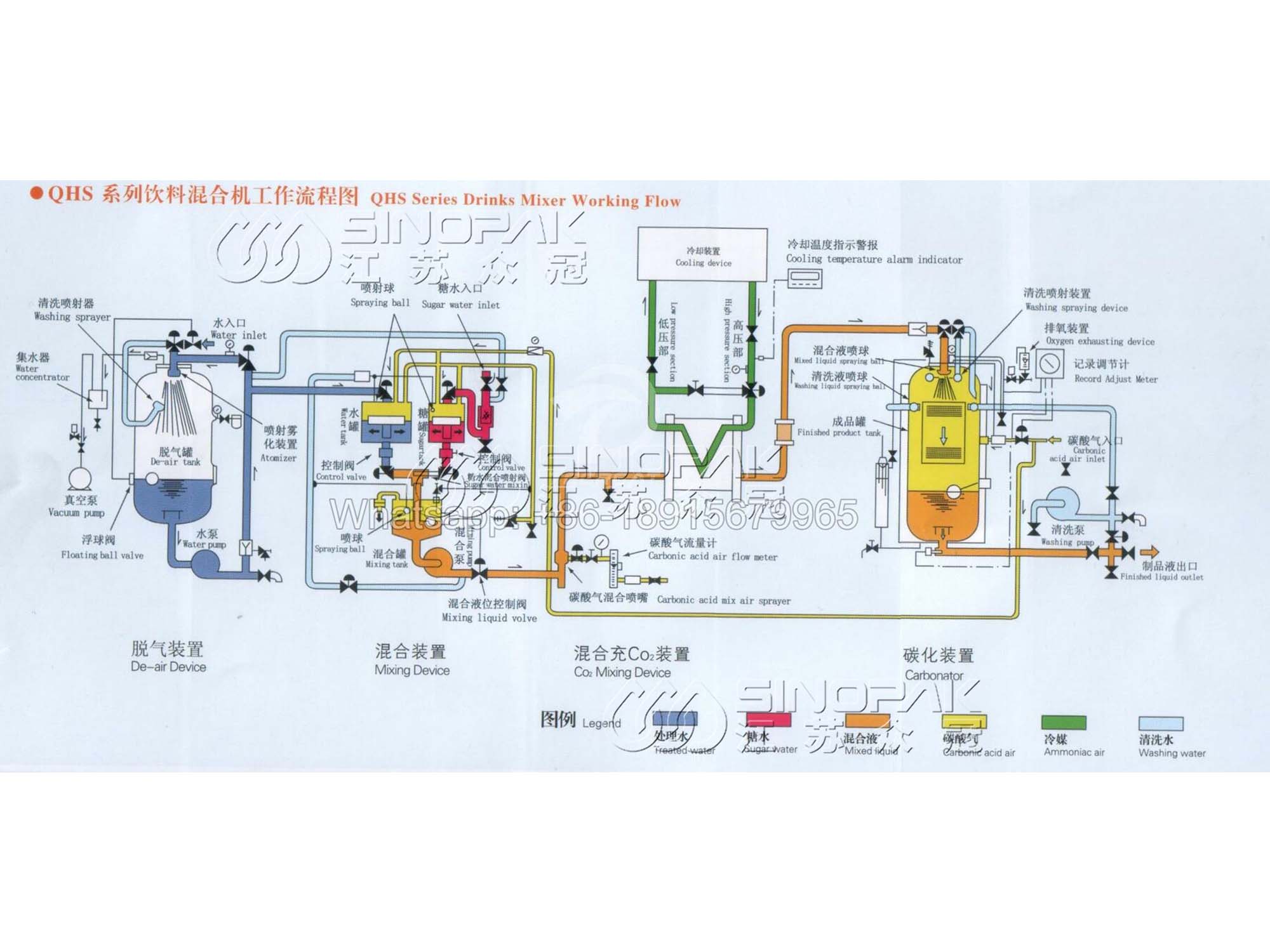

Description

Syrup Melting Tank :

It widely used in candy, pharmacy, dairy food, pastry, drink, can ect, also can be used in large restaurant or dining room to boil soup, cook, stew, boil congee, etc.. it is a good equipment of the food processing to improve quality, shorten the time, improve working conditions

Function: to preparing the syrup

Blend tank/ Mix tank:

Stir, mix, blend, and homogenize the materials. The design structure and configuration can be standardized according to the requirements of the production process. Stirred tank during agitation can be achieved feed control, the feed control, stirring and other manual controls automatic control

CO2 Mixer:

Beverage Mixing Machine is used to mix CO2 with beverage, it is suitable for all types of carbonated drink processing. It is the necessary and important beverage mixing machine for carbonated drink processing

The beverage carbonator is used for mixing all kinds of carbonated drink with high gas ration.

It mixes the water, sugar, gas together for high quality gas drink, adopts the newest technology.

Chiller:

Drinking Water Chiller, Carbonated Drink Mixer Chiller, Wort Chiller for Beverage Processing.

The chillers are special designed for beverage processing, maintain temperature at 4 deg. c. The heat exchange unit is made up of stainless steel 304 food grade Hygienic step tubes.