Description

Features:

- Man-machine Interface control, easy to operate

- Automatic preform loading and unscrambling

- Preform hopper

- Stable preform alignment, loading preforms according to capacity

- Close structure, low contamination

- Well preform heating system

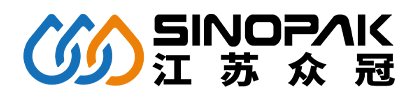

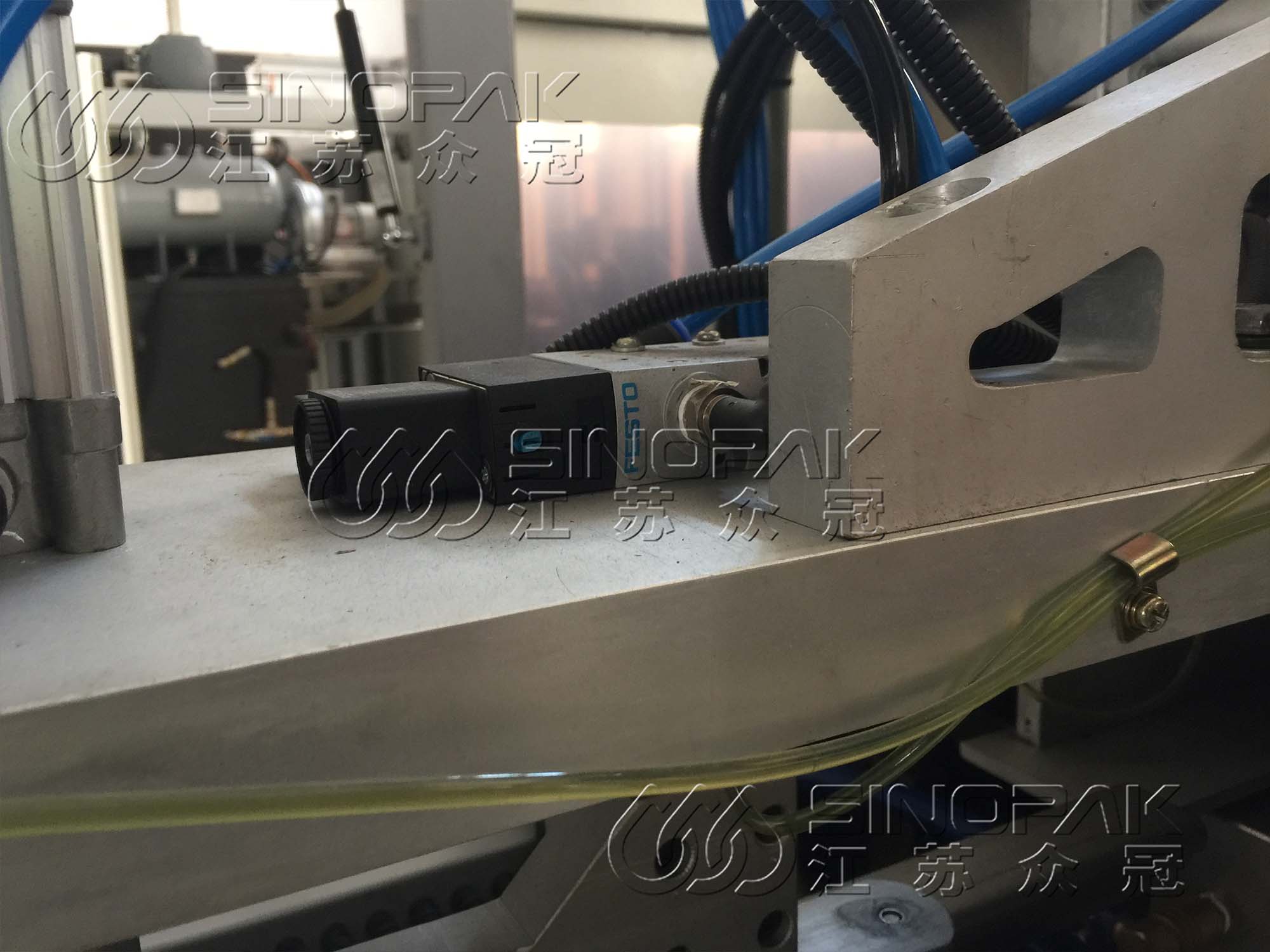

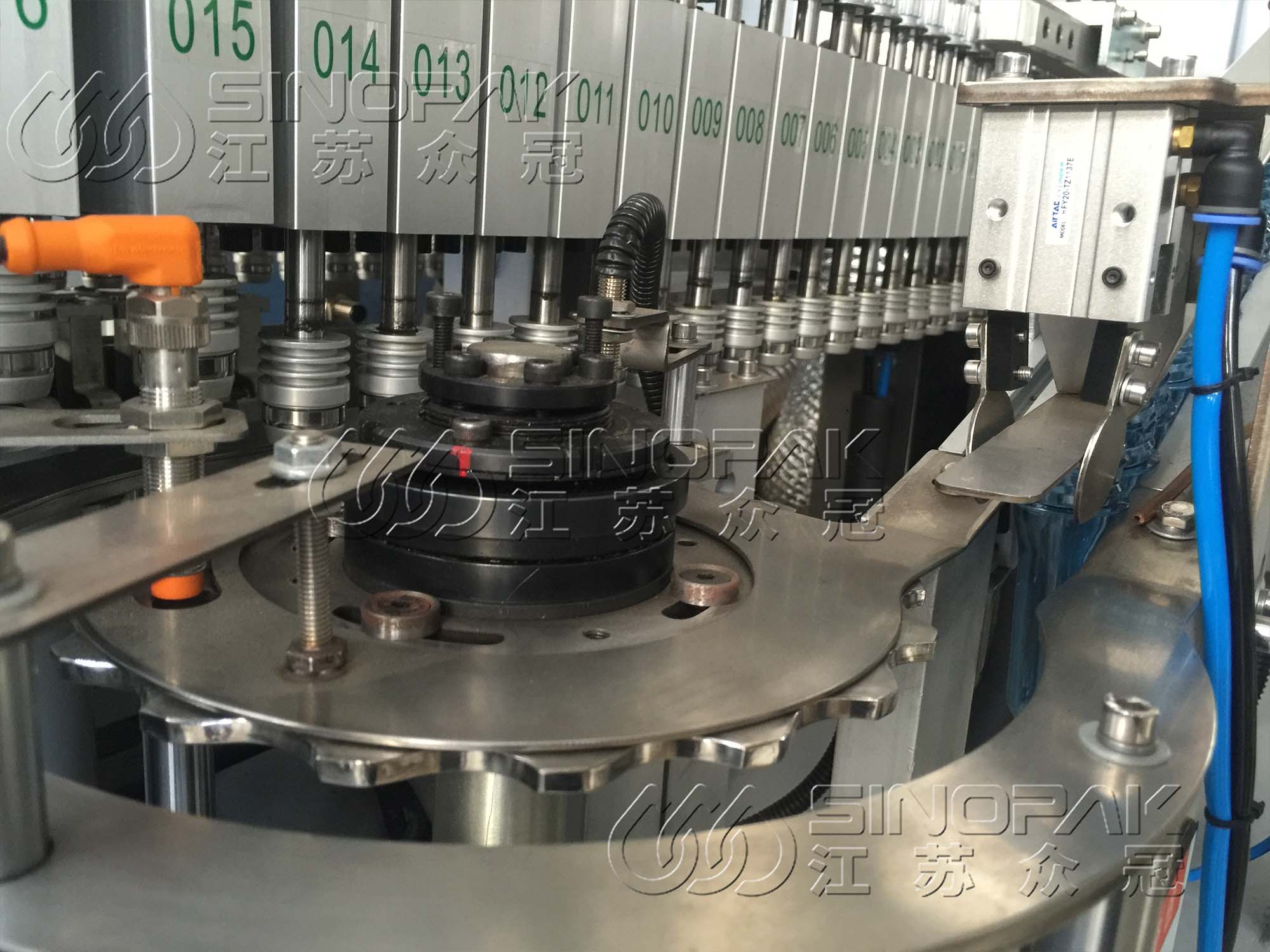

- Stable rotating system

- Preforms are evenly heated, and easy to blow

- Low energy consumption, heating capacity is adjustable

- Recycling air cooling system in oven (option)

- Heating system is a mutual feedback and closed loop system, can works in a constant power output, without being affected by voltage fluctuation.

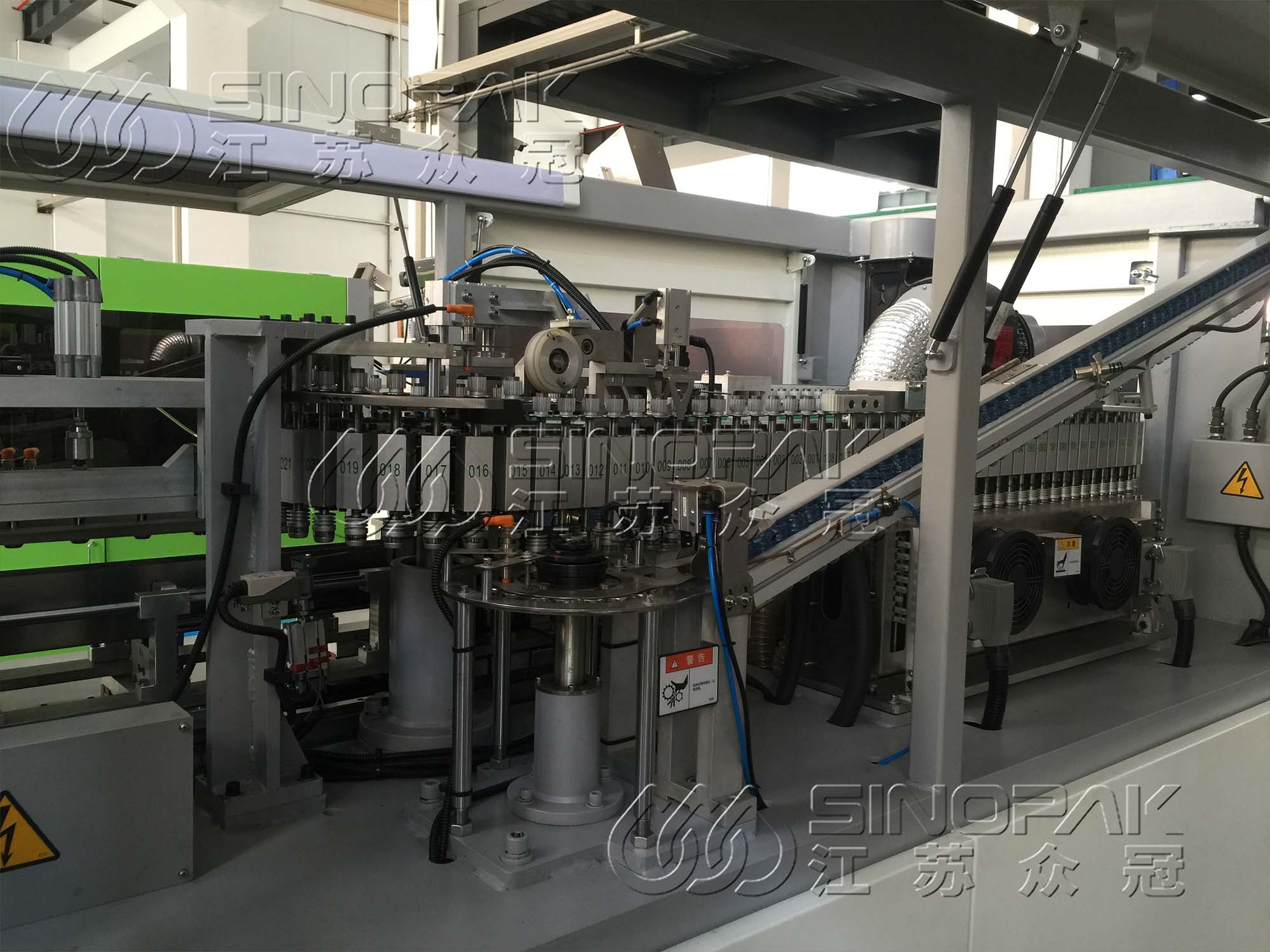

Preform loading, bottle fetching and outputting:

2.Preform loading, bottle fetching and outputting

All the preform loading and bottle fetching and out putting movements are finished by mechanical transfer arms, which avoid contamination.

Change moulds:

The whole moulds changing takes only one hour.

Highautomation, low contamination:

Fully enclosed design, finished bottle is transferred by mechanical arms and conveying belt, the whole production process avoids human contact, thus ensuring a healthy and cleaning environment which meets national health standards.

Stableand reliable performance:

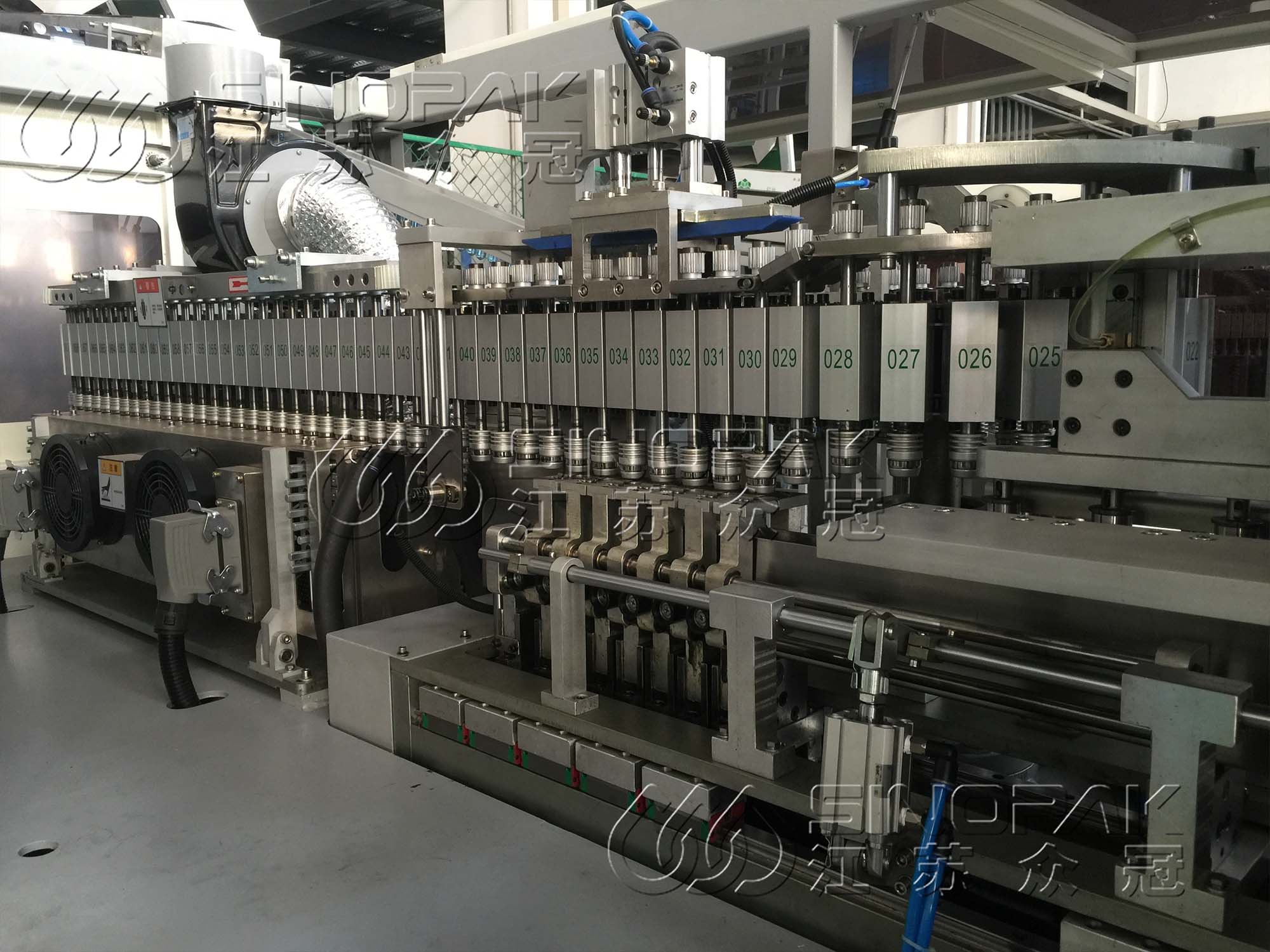

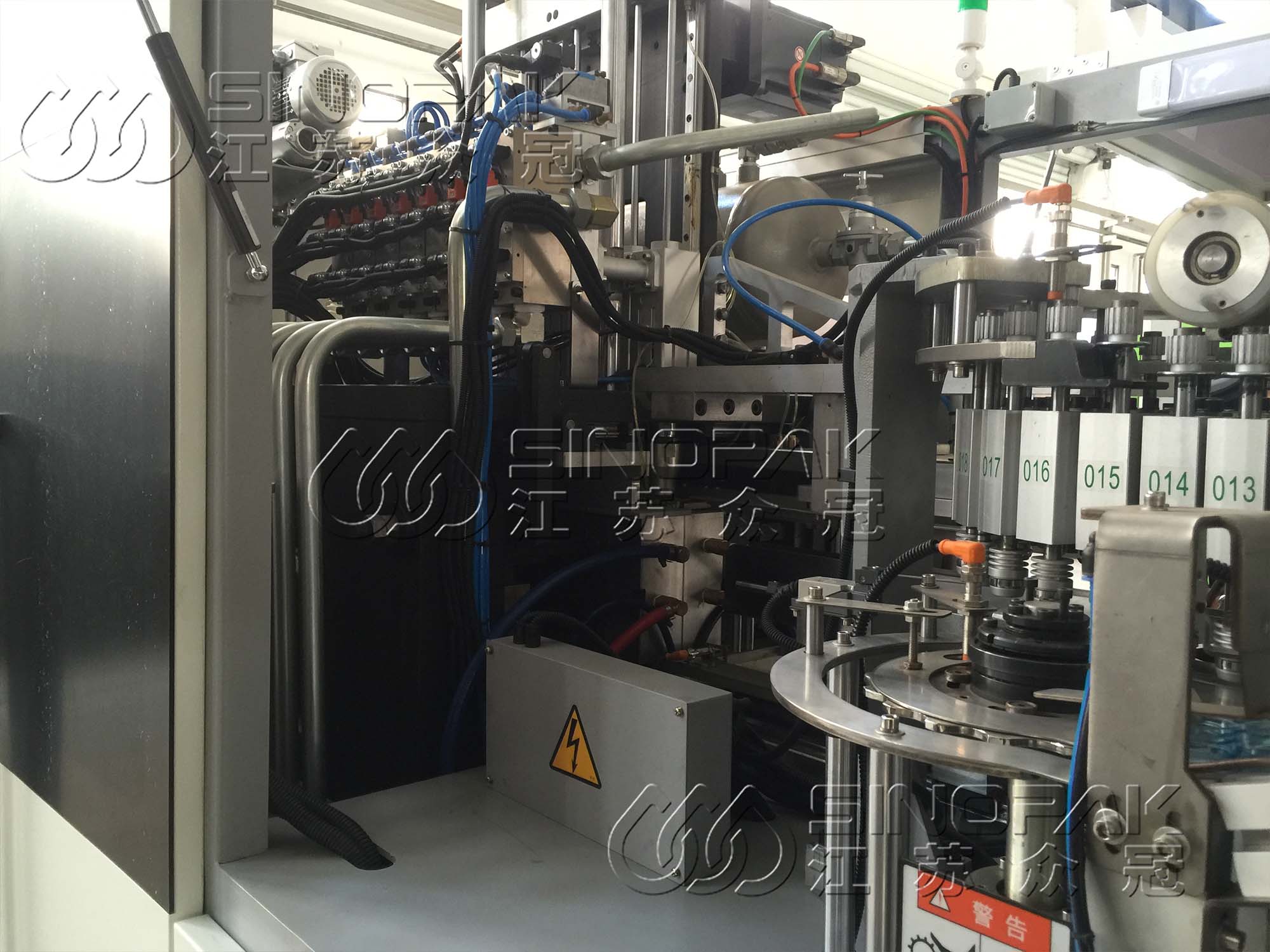

All the important parts, such as electric and pneumatic components, seals, bearings, and reducers, etc., are European orJapanese brands, ensuring a high qualified machine and reliable performance.

Human-machine Interface:

HMI, with a variety of parameters setting function, is easy to operate. Operators can modify the parameters while the machine is running, such as the pre-blowing, second blowing, blowing time, etc.

Easy maintenance:

PLC communicates with machine through a specific cable connection. User can control every movement of the machine through this PLC. Once there is a failure, machine will alarm and display the problem. Operator can easily find the reason and solve the problem.

Machine Parameters:

| Model | SPB-4000S | SPB-6000S | SPB-8000S | SPB-10000S |

| Cavity | 4 | 6 | 8 | |

| Output(BPH) 500ML | 6,000 pcs | 12,000 pcs | 16,000 pcs | 18000pcs |

| Bottle size range | Up to 1.5 L | |||

| Air consumption | 6 cube | 8 cube | 10 cube | 12 |

| Blowing pressure | 3.5-4.0Mpa | |||

| Dimensions (mm) | 3280×1750×2200 | 4000 x 2150 x 2500 | 5280×2150×2800 | 5690 x 2250 x 3200 |

| Weight | 5000kg | 6500kg | 10000kg | 13000kg |