Description

Main Features:

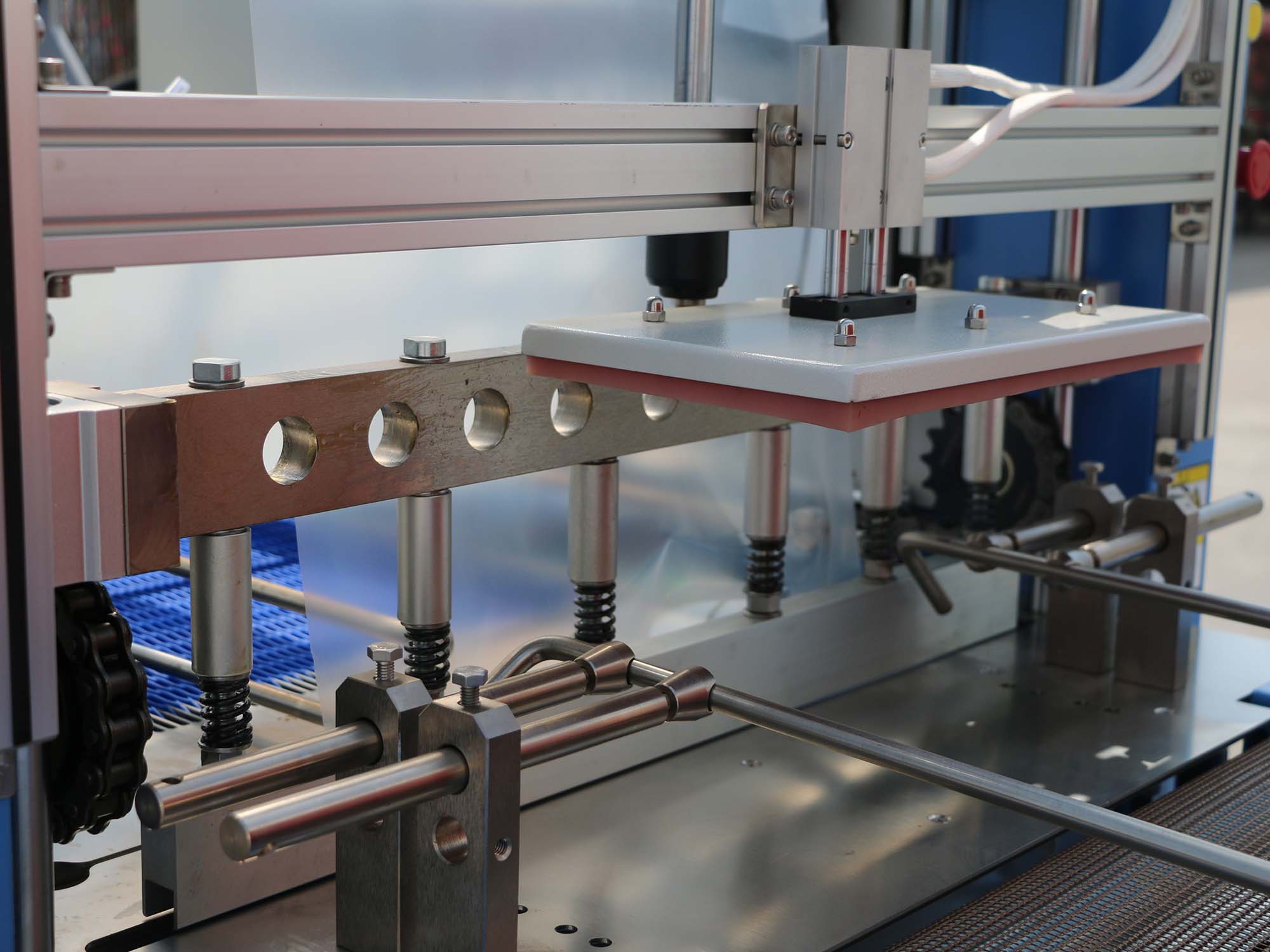

- The sealing adopts the advanced structure of hot sealing and hot cutting, with firm sealing, neat edge, good sewing performance and no flash.

- Linear bottle feeding, small space occupation, convenient layout, stable transportation and high efficiency.

- Comprehensive protection function: when there is an obstacle at the sealing and cutting place, the equipment will be protected and an alarm will be given at the same time to prevent the package from being damaged.

- Adopt plastic steel chain conveyor belt, long-term use, no deformation, small jump, stable transportation.

- Unique patent subcontracting mechanism, accurate and stable subcontracting, convenient adjustment.

- Precise PID temperature controller, precise temperature control.

- The shrinking machine adopts a unique patented hot air diversion and circulation system, with adjustable air flow and natural heat recovery. The patented furnace structure not only achieves good packaging effect, but also plays the best role in energy saving. *The shrinkage furnace adopts special heat preservation structure, which can not only reduce energy consumption, but also ensure the safety of workers’ operation.

Technical Parameters:

| Project Name: Shrink Wrap Packing Machine | |||||

| Degree Of Automation | Semi Automatic | Full Automatic | |||

| Model | TSP-10A | TSP-15A | TSP-25A | TSP-30A | TSP-40A |

| Power Supply | 3PH 380V/50HZ | ||||

| Gas Source | ≥0.5MPa | 0.6~0.8MPa | |||

| Overall Dimension Of Equipment (mm) | L5850 *W1200 *H1900 | L5850 *W4000 *H1900 | L9000 *W1100 *H1900 | L13200 *W1100 *H2000 | L13240 *W1260 *H2030 |

| Maximum Package Size(mm) | L450 *W400 *H390 | L450 *W300 *H390 | L450 *W450 *H350 | L500 *W450 *H350 | L500 *W450 *H350 |

| Packing Efficiency (bag/minute) | 6-12 | 10-15 | 15-20 | 20-25 | 25-36 |

| Maximum Sealing Length(mm) | 620 | 650 | 700 | 700 | 700 |

| Power(Kw) | 23.8-29.8 | 24.2-30.2 | 35 | 26-32 | 35 |

| Working Surface Height(mm) | 850±30 | 900±30 | 900±30 | 900±30 | 900±30 |

| Applicable Film | PE | ||||