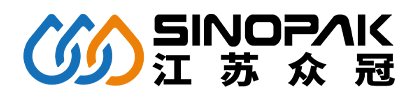

Description

Main Features:

- Control system: SIEMENS PLC control system, with high stable operation and extremely low failure rate;

- Operation system: SIEMENS touch screen, with Chinese and English language, rich with help function and fault display function,easy operation;

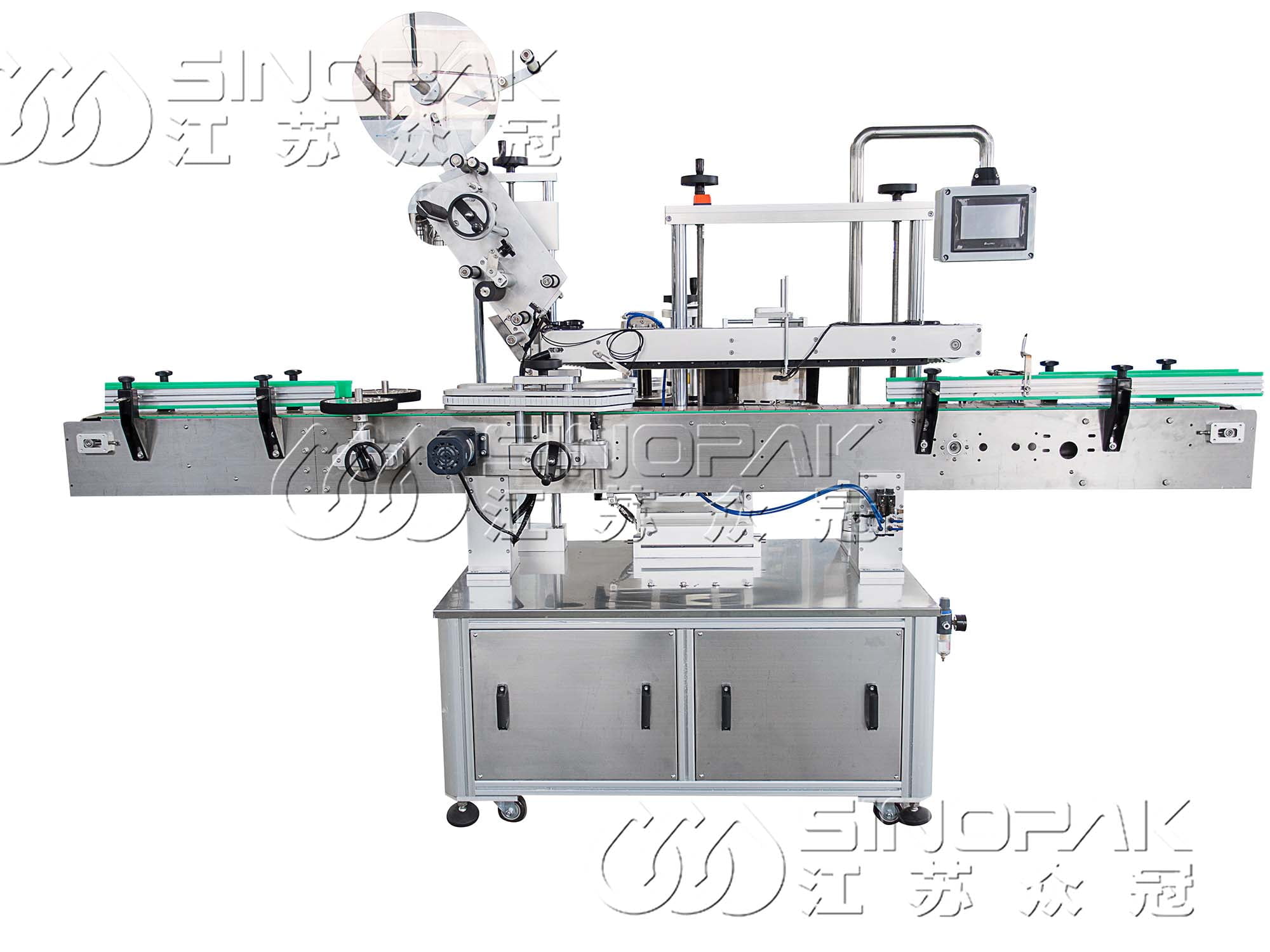

- Check system: German LEUZE check label sensor, automatic check label position, stable and convenient don’t have much higher requirement for the worker skill;

- Send label system:American AB servo motor control system, stable with high speed;

- Alarm function : such as label spill, label broken or other malfunction during machine working all will alarm and stop working.

- Machine Material:The machine and spare parts all use material S304 stainless steel and anodized senior aluminum alloy,with high corrosion resistance and never rust;

- Low voltage circuit all use the France Schneider brand.of the man-machine interface, the key electrical components are adopted internationally renowned products

Working Process:

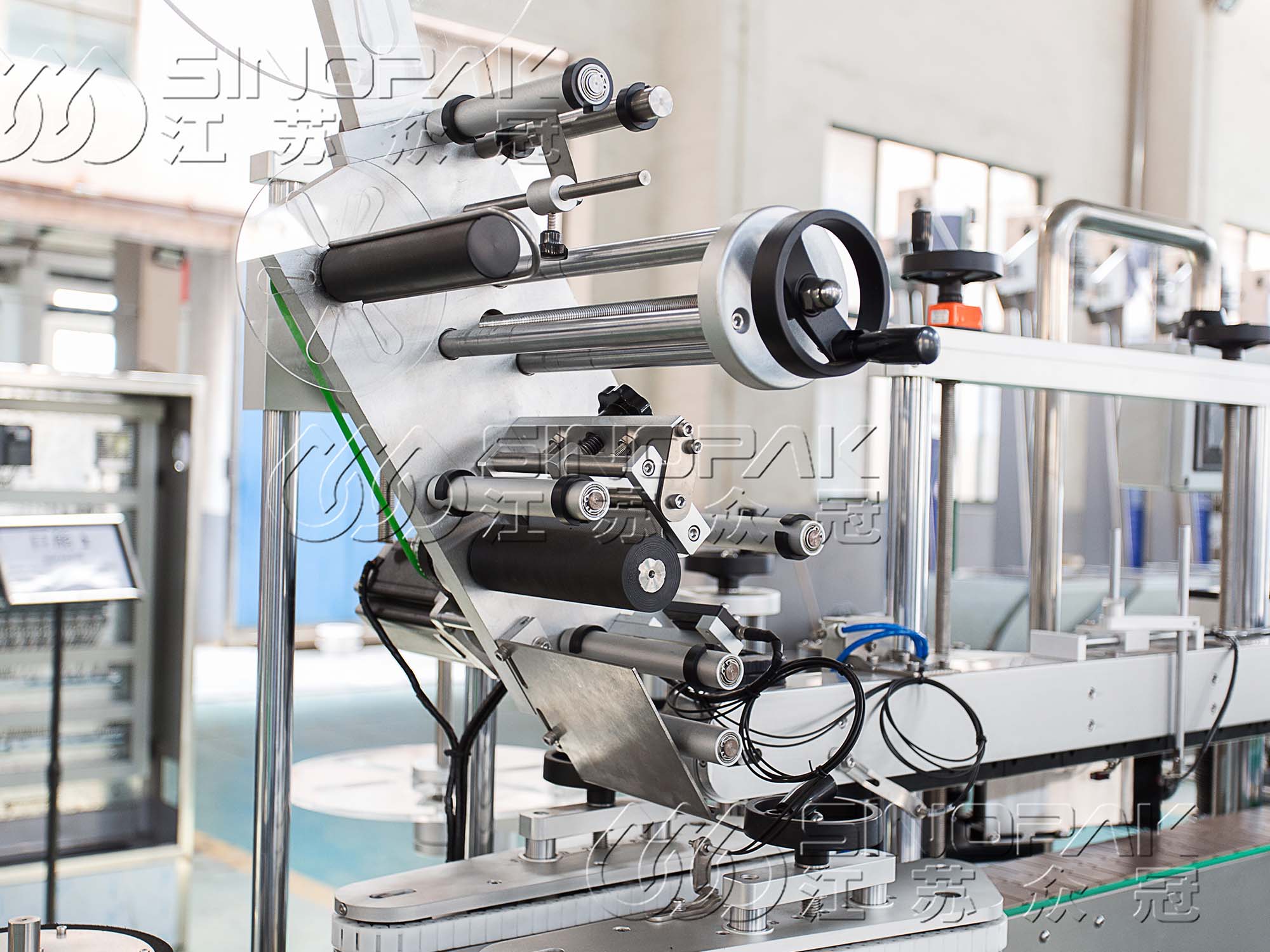

- Products delivery to clamp device, keep products not moving;

- When sensor check Product, send signal to PLC, PLC received signal deal with information first, then output signal to servo motor driver, driven by the drive motor send label. Brush label device past label on product top surface first, then air cylinder brush label device brush label down on the bottle side surface, labeling finish.

The Sketch Map:

Parameters:

| Name | Economy Round Bottle Labeling Machine |

| Labeling Speed | 20-200pcs/min(Depending on label length and bottle thickness) |

| Height of Object | 30-280mm |

| Thickness of Object | 30-120mm |

| Height of Label | 15-140mm |

| Length of Label | 25-300mm |

| Label Roller Inside Diameter | 76mm |

| Label Roller Outside Diameter | 380mm |

| Accuracy of Labeling | ±1mm |

| Power Supply | 220V 50/60HZ 1.5KW |

| Gas Consumption of Printer | 5Kg/cm^2 |

| Size of Labeling Machine | 2200(L)×1100(W)×1300(H)mm |

| Weight of Labeling Machine | 150Kg |

Configuration List:

| List of Standard electricl appliance Configuration | |||||

| Module name | Electric appliance name | Type | Quantity | Merchant | Place of production |

| Machine frame fluctuation unit | Low power a-c dynamo | 5IK90GU-CF-5GU30KB | 1 | TWT | Taiwan |

| Clean-down unit | Low power a-c dynamo | 5IK120A-CFT | 1 | TWT | Taiwan |

| Feeding unit | Low power a-c dynamo | RV50-15K-180 | 1 | TWT | Taiwan |

| Frequency converter | VFO-0.25KW | 1 | Panasonic | Japan | |

| Photoelectricity inductor | CX-421 | 1 | Panasonic | Japan | |

| Bottle Carrying unit | Low power a-c dynamo | 5IK90GN-YFT-5GN20K | 1 | TWT | Taiwan |

| Frequency converter | VFO-0.25KW | 1 | Panasonic | Japan | |

| Bottle Separation unit | Low power a-c dynamo | 5IK90GN-YF-5GN10K | 1 | TWT | Taiwan |

| Frequency converter | VFO-0.25KW | 1 | Panasonic | Japan | |

| Hairbrush unit | Low power a-c dynamo | 4IK25GN-CFT-4GN3K | 2 | TWT | Taiwan |

| Cutter head unit | Cutter head servo motor | MHMD042P1U(400w) | 1 | Panasonic | Japan |

| Cutter head servo driver | MBDDT2210003(400w) | 1 | Panasonic | Japan | |

| Minitype photoelectricity inductor | PM-L44 | 2 | Panasonic | Japan | |

| Driving unit | Driving servo motor | MHMD042P1U(400w) | 1 | Panasonic | Japan |

| Driving servo driver | MBDDT2210003(400w) | 1 | Panasonic | Japan | |

| Electric eye unit | High speed fibre-optical inductor | FX-301 | 1 | Panasonic | Japan |

| Bottle monitor unit | Photoelectricity inductor | CX-442 | 1 | Panasonic | Japan |

| Conveyor unit | Frequency converter | VFO-0.75KW | 1 | Panasonic | Japan |