Description

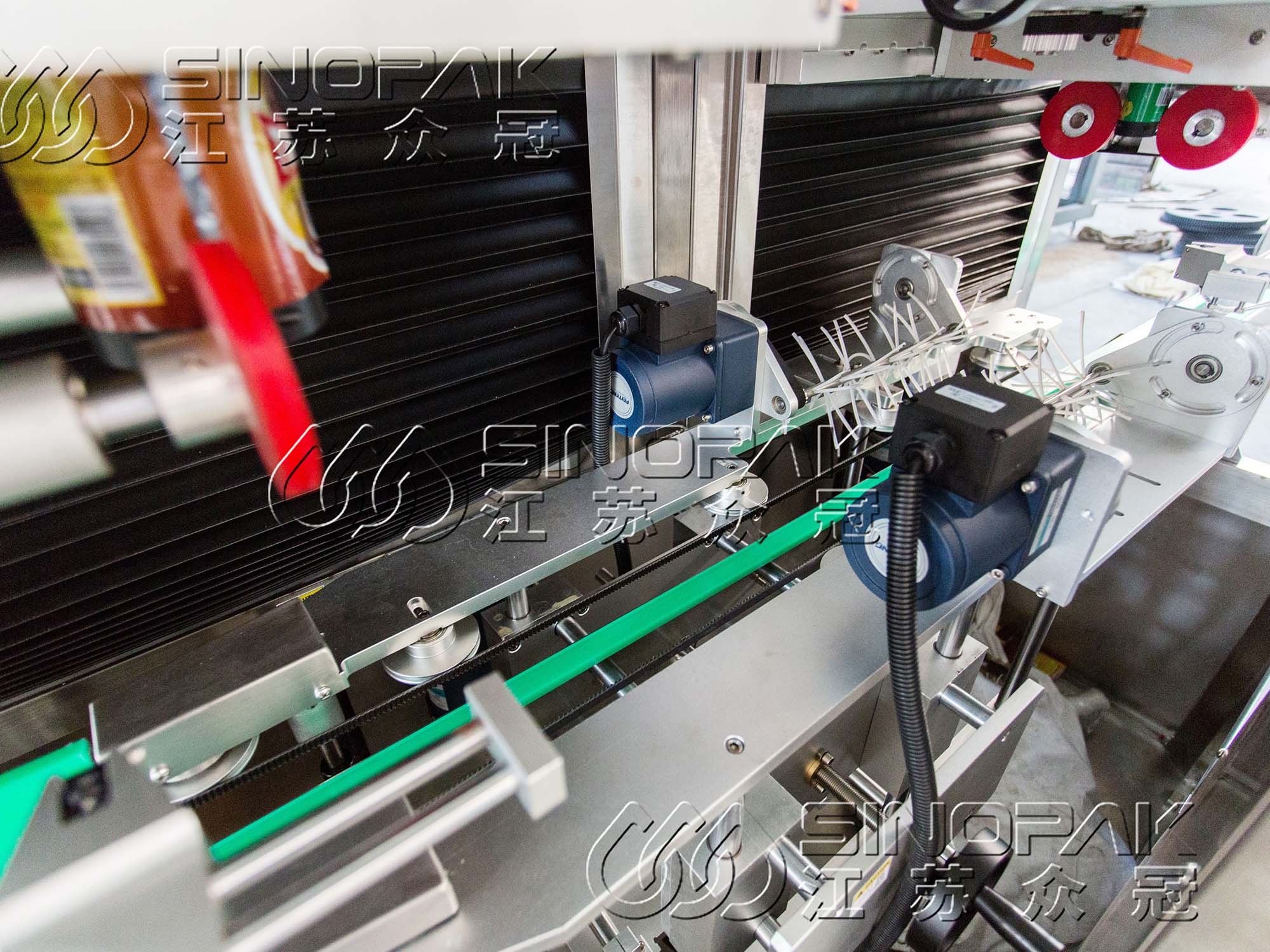

Main Features:

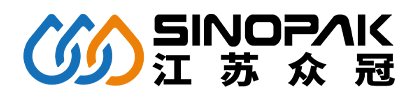

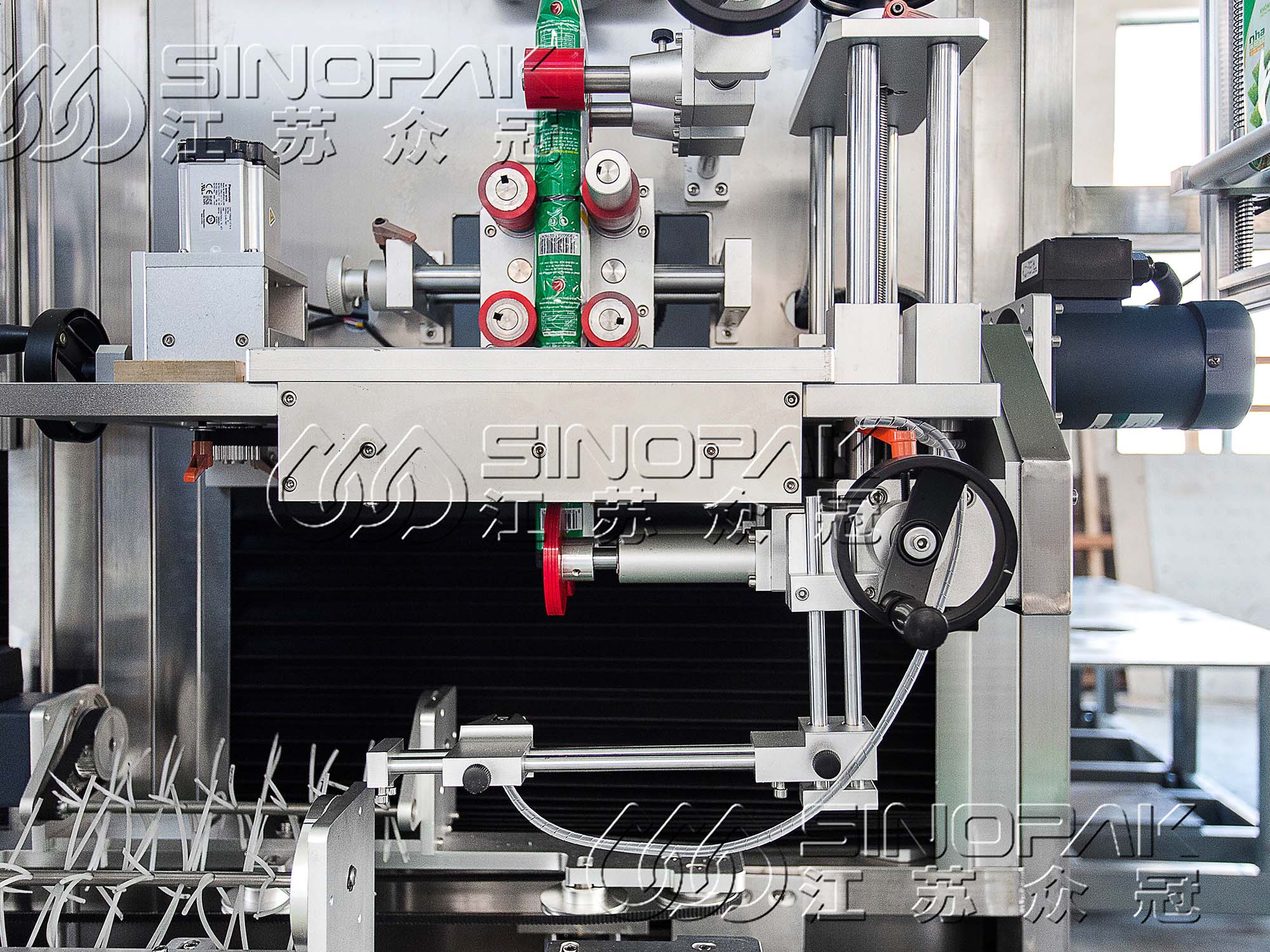

- Body is built with stainless steel, steel construction stable and not rust.

- The whole machine used quick release type of construction. In order to change and adjustment easier.

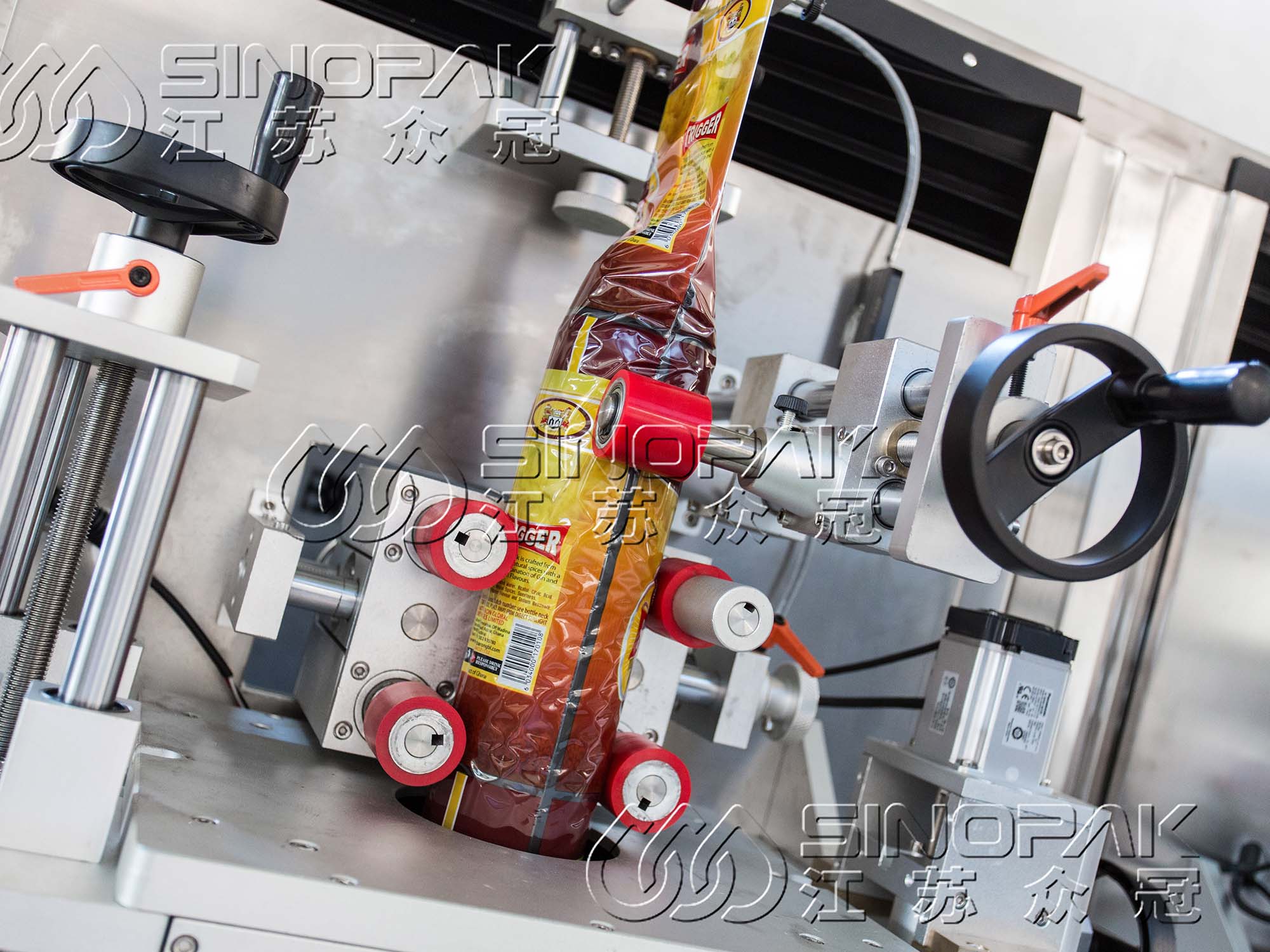

- Centralized lubricating system for simple and effortless on maintenance, lubrication and cleanness.

- With photo-sensors to detect label output and automatically self-regulated production speed for integrating production line with other machines.

- Used stable and reasonable of compiling program. It can be suitable for operation 24 hours.

- The bottle working mode is linear Input and output type.

- Equipped with the Torque limiter would control the torsion range abnormal situation of machine. It will reduce the accident for operate.

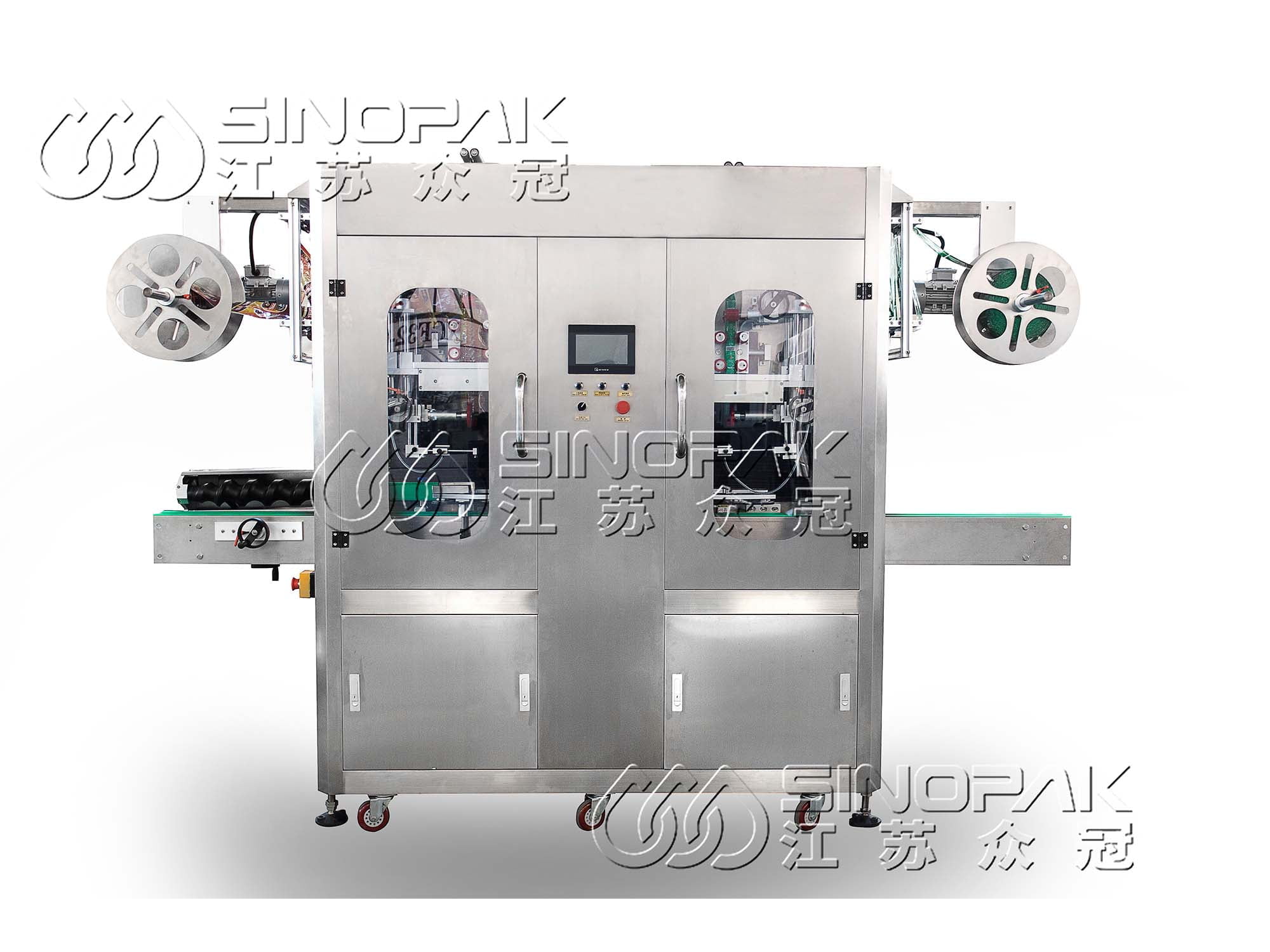

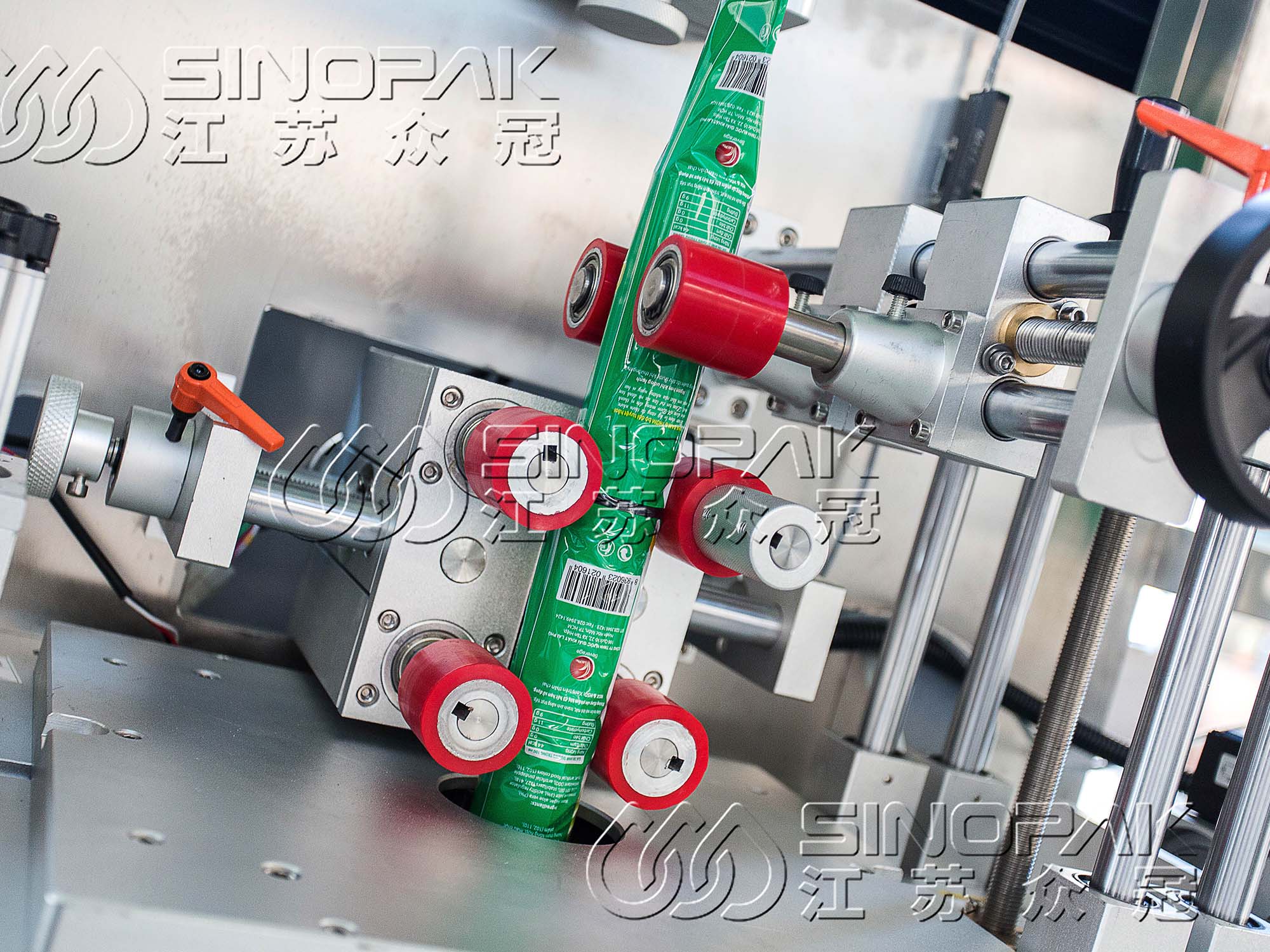

- Roller coating, gluing balance and glue saving.

- Alarm system: Caution light & buzzer for out of label, Label break and door open!

- Cut label system: Used multiple cure of cut system organization. (It is not quick-wear part)

- The machine production speed is control by the machine input bottle signal. It is automatic transmission. If input bottle stock, then the machine will be increase speed. If input bottle did not have bottle the machine will transmission speed slow.

- The machine production speed is control by the machine input bottle signal. It is automatic transmission. When the machine output bottle stock then the machine will be transmission speed to slow. If output bottle is smooth the machine will be increase the speed.

Machine Applications:

The mainly used for container labeling cylindrical shape of detergents, beverages, mineral water, food etc. The material of label is using environmentally material of OPP films.

Parameters:

| Model | OPP-100 | OPP-200 | OPP-300 | OPP-400 |

| Speed of labeling | 6000BPH | 8000BPH-12000BPH | 15000BPH-18000BPH | 20000BPH-24000BPH |

| Power | AC 3ψ380V50Hz |

| | | | |

| Efficiency | ≥99.5 | ≥99.5 | ≥99.5 | ≥99.5 |

| Accuracy of labeling | ±1mm | ±1mm | ±1mm | ±1mm |

| Diameter of bottle | 40-110mm | 40-100mm | 40-100mm | 40-100mm |

| Material of bottle | Glass, Metal, Plastic | Glass, Metal, Plastic | Glass, Metal, Plastic | Glass, Metal, Plastic |

| Shape | Round | Round | Round | Round |

| Label material | OPP,BOPP,PAPER | OPP,BOPP,PAPER | OPP,BOPP,PAPER | OPP,BOPP,PAPER |

| Label thickness | 0.035-0.05mm | 0.035-0.05mm | 0.035-0.05mm | 0.035-0.05mm |

| Label height | 40mm-180mm | 40mm-150mm | 40mm-180mm | 40mm-150mm |

| Inside diameter of paper tube | 6inch | 6inch | 6inch | 6inch |

| Air source | 0.5Mpa | 0.5Mpa | 0.5Mpa | 0.5Mpa |

| Rated power | 10KW | 10KW | 12kw | 12kw |

| Machine size | 3176L*1500W*2050H(mm) | 5000L*1600W*2000H(mm) |

| Weight | 2000kg | 2500kg | 3200kg | 3500kg |

Parameters:

| Fully enclosed Host | Door stop |

| send bottles | Screw or star wheel |

| Feeding bottle | cylinder |

| Separate bottle | Stars Wheel |

| Sending label | servo encoder control |

| Illumination | LED, top + bottom access operation lamp lights + electrical control box overhaul lights |

| Fixed feeding shelf | Removable standard planar fast. (Optional double frame) |

| Touch screen | single touch |

| Cabinet work | Column cabinet manually unscrew the formula |

| Corrective devices | Germany E + L |

| Alarm system | warning light & buzzer, lack of material, marked off, open the door |

| Label system | Physical adjustable friction brake feed |

| Transmission systems | machine connections, independent label transmission |