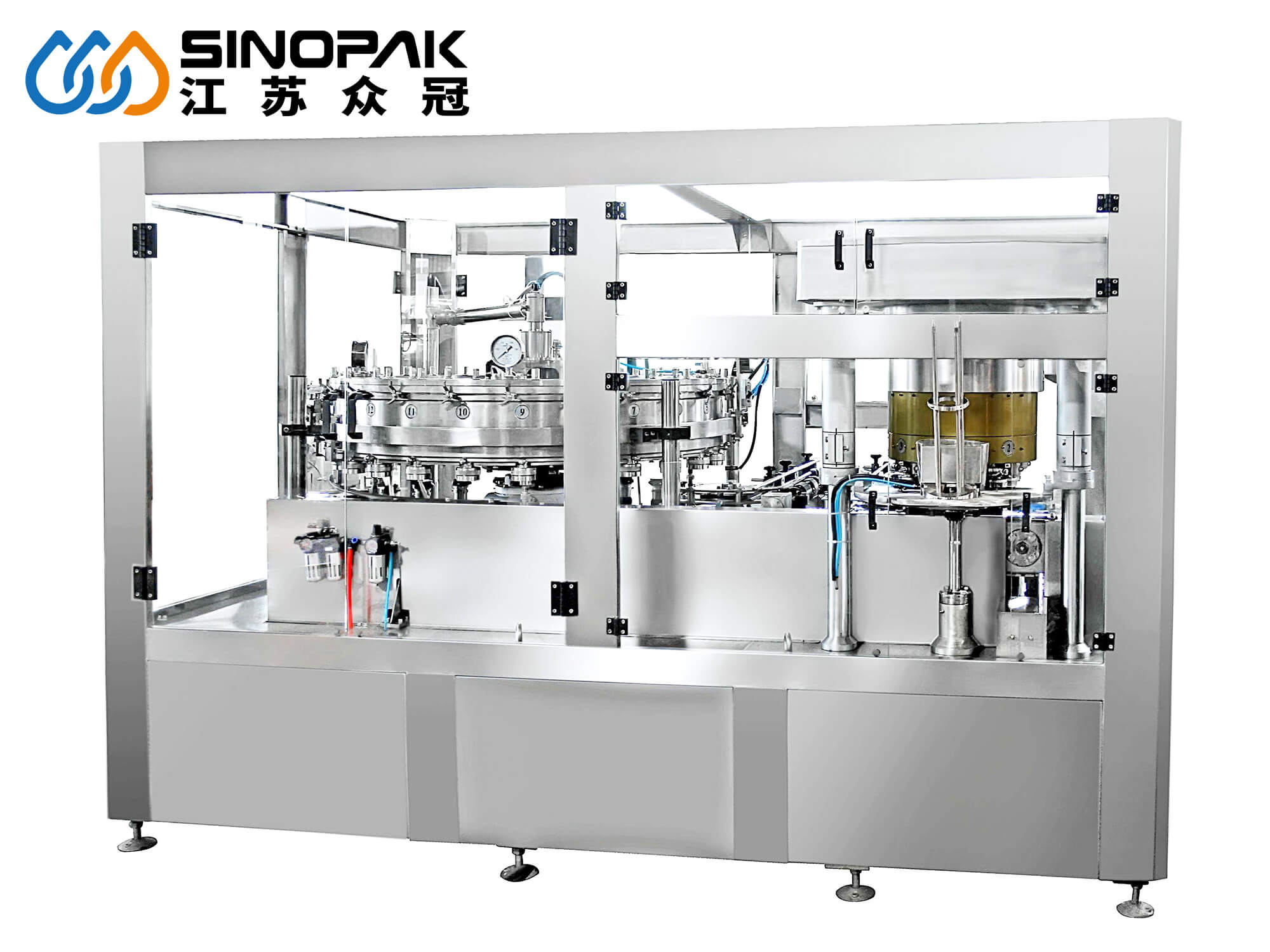

Description

Filler Station :

- High precision filling nozzle , ensure high filling precision & filling smoothly & steadily,

- Isobar Pressure filling nozzles which ensure minimal loss of CO2 from the drink

- All 304 stainless steel contact parts & liquid tank, fine polish, easy to clean

- CIP ( clean in place) sideway pipeline in-build, can connect with CIP station or Tap water to clean

Capper Station :

- Electromagnetic sealing heads

- All 304stainless steel construction

- No cans no sealing and Automatic stop when lack of sealer

Electric Part & Safe Device & Automation:

- When accident system automatic stop & alarm

- Emergency switch when accident

- PLC control full-automatic working, inverter in-build, speed adjustable

- Touch-screen Control Panel, easy operate

- Famous Omron brand sensor & other electric parts adopted, ensure system heavy duty running

Capping Part :

- Cap distributing chute is equipped with reverse cap stop and reverse cap pick-out mechanism.

- Cap distributing chute is equipped with a photocell switch to stop the capper when there is no cap inside the chute.

- The capper is equipped with inlet bottle detection switch.

- Centrifugal way of cap arranging is adopted to reduce damage of caps.

Machine Base & Machine Construction::

- 304 stainless steel frame

- Excellent start wheel design, easy change over parts

- Machine Base with anti-rust process, ensure the forever antirust

- All seal where liquid may Leakage & base neck come with rubber, water proof

- Manual lubrication system

Machine Parameters

| Model | TFS-D-6-1 | TFS-D-12-1 | TFS-D-12-4 | TFS-D-20-4 | TFS-D-30-6 | TFS-D-60-8 |

| Capacity(BPH) | 600-800 | 1500-1800 | 4500-5000 | 12000-13000 | 17000-18000 | 35000-36000 |

| Suitable bottle | PET Can,Aluminum Can ,Iron Can and so on | |||||

| Filling precision | ≤±5mm | |||||

| Filling pressure | ≤0.4Mpa | |||||

| Powder(KW) | 2 | 2.2 | 2.2 | 3.5 | 3.5 | 5 |